Materials Recommended for Water Leak Prevention

|

Leak zones

|

Recovery materials

|

|

Windscreen, rear window

|

Urethane adhesive, putty kit or equivalent

|

|

Metal connections

|

Brush-applied joint sealant that can be painted over

|

|

ventilation ducts

|

3M™ Automotive Glazing Compound or equivalent

|

|

Small cracks and holes

|

3M™ Anti-condensation Sealant or equivalent

|

|

Large holes

|

3M™ Automotive Seam Sealant

|

|

Seals

|

3M™ 08011 Sealant Adhesive or equivalent

|

|

Bolts, studs and screws

|

Sealing putty

|

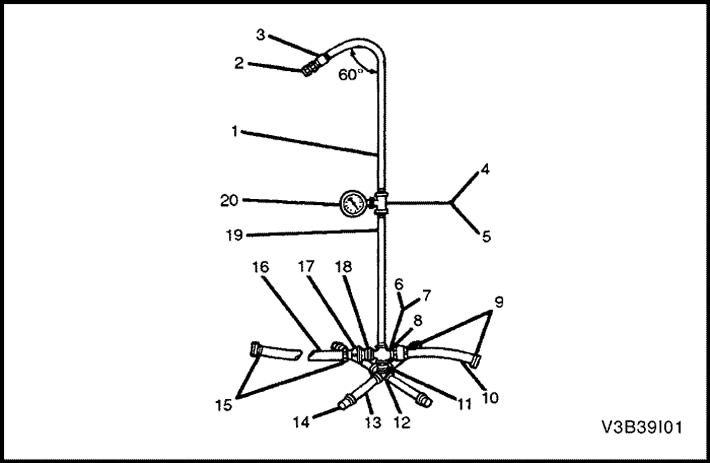

Specifications of the water test stand

|

PROGRAM

|

Description

|

|

nozzle type

|

No. 1/2 GG-25 full jet spray nozzle or equivalent with 60°internal angle.

|

|

nozzle height

|

Approx. 1600 mm (63 inches) from the floor

|

|

Consumption

|

14 l (3.7 gallons) in a minute

|

|

Pressure

|

155 kPa (22.5 psi inch) on the nozzle

|

|

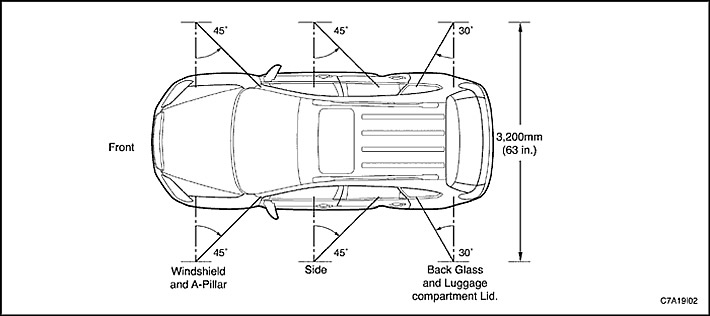

Position of the windshield and A-pillar test stand

|

Approximately 30°down, 45°back, pointing at the corner of the windshield

|

|

Position of the center column test stand

|

Approximately 30°down, 45°back, directed towards the center of the tailgate

|

|

Position of the rear window and rear end door test stand

|

Approximately 30°down, 30°forward and pointed at approximately 610 mm (24.0 inches) from the corner of the rear window

|

Water leak diagnostics

Elimination of water leakage into the housing requires appropriate testing and diagnostics. Water leakage should be corrected by adjusting non-mating parts and using the proper repair materials. First, the conditions causing the leak should be identified. For example, a leak may only occur when the vehicle is on a slope, or water may only appear in the spare wheel well. Secondly, the area under investigation should be checked for the presence of a source of leakage using the following methods. If a general leak is found, locate the exact leak using a water or air hose. If a general leak area is not obvious, water test benches should be used to identify it. It may be necessary to remove some interior upholstery panels or some parts in order to find a leak.

Important: Before starting any repair work, you must find the source of all leaks. Random repairs can only stop a leak temporarily and make further repairs more difficult. Localized testing should continue in the general area to detect any leaks.

General tests

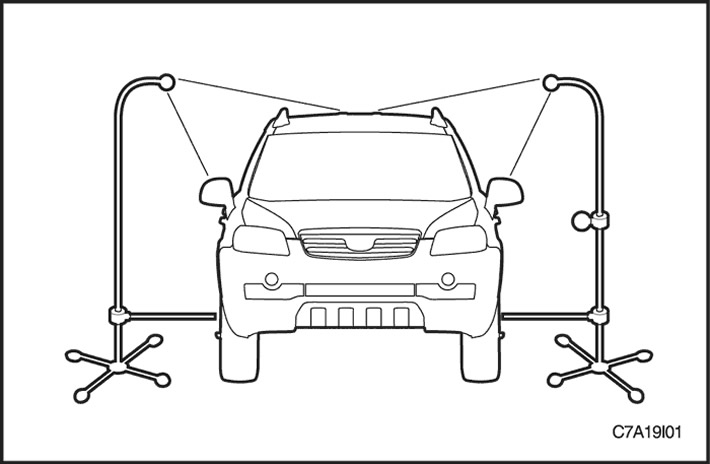

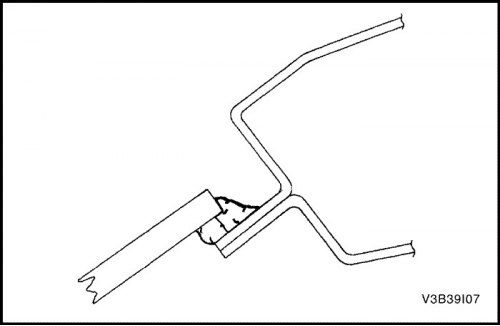

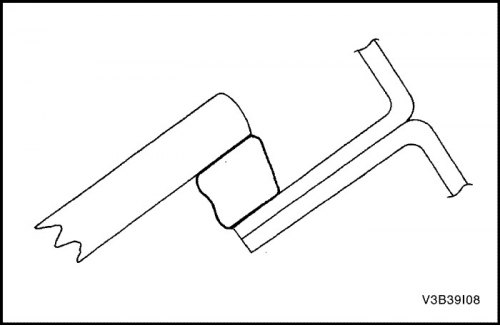

1. Assemble water test benches.

- Pipe 1/2" x 36"

- Full jet nozzle #1/2 GG-25 or equivalent, 1600mm from the floor

- 1/2" coupler

- Reducing Tee 1/2" to 1/2" to 1/4" (only on the right)

- 1/2" coupler (only on the left)

- 1/2" cross (only on the right)

- 1/2" tee (only on the left)

- 1/2" tube to hose (only on the right)

- 5/8" Female Hose Coupling

- 5/8" inlet hose (length 61 cm (2 feet), only on the right)

- 1/2" closed stub

- 1/2" cross with weld-on 1/2" tip

- Spigot 1/2" to 12"

- 1/2 inch tip

- 5/8" Female Hose Coupling

- 5/8" cross hose (3.66 m long (12 feet))

- 5/8" hose quick coupling

- 1/2" tube to hose

- Pipe 1/2" x 30" (straight)

- 1/4" water pressure gauge (only on the right)

2. Prepare for the water test.

3. Conduct a water test. See «Specifications of the water test bench» in this section.

4. If the local water pressure does not reach the required value of 155 kPa (22.5 psi inch), move both stands closer to the vehicle so that the jets of water overlap each other.

Localized test (spot check)

1. Carry out a localized test with a water or air hose.

2. Start the test by spraying air or water at the base of the suspected leak. Continue spraying air or water in an upward motion until a leak is found.

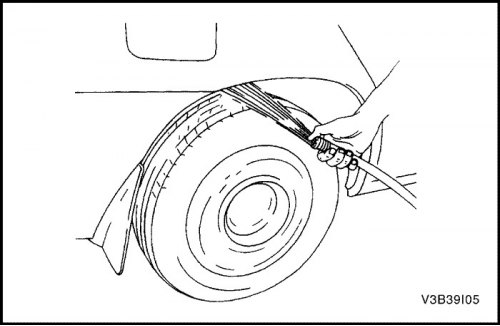

Water hose test

1. Have another person get into the vehicle to locate the leak.

2. Use a water hose without a nozzle.

3. Start spraying water at the base of the suspected leak area. Continue spraying water in an upward motion until a leak is found.

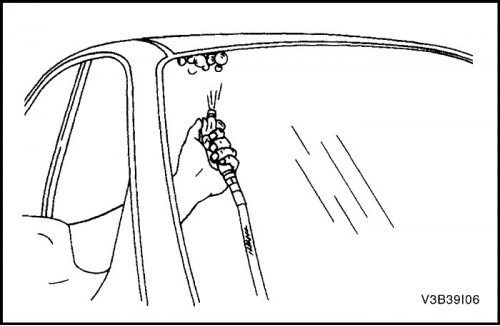

Air hose test

1. Apply soapy water to the outer surface of the car in the expected area of leakage.

2. Supply air from inside the vehicle. Air pressure must not exceed 205 kPa (29.7 psi inch).

3. Determine the location of the leak by the bubbles formed in the soapy water.

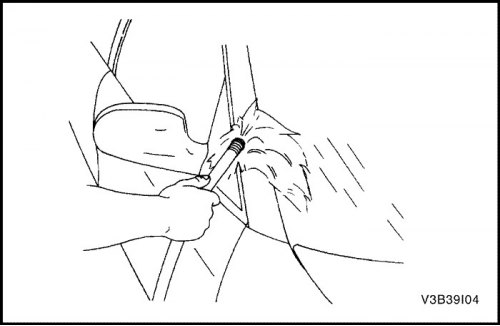

Elimination of water leakage

Some leaks around the glass can be repaired without removing the glass.

Important: This repair can only be done on urethane-mounted glass.

1. Remove the protective molding in the area of leakage. It may be necessary to remove the decorative molding or some of the interior trim panels to find a leak.

2. While spraying water on the leak area, gently push the glass outward to determine the size of the leak.

3. Mark the leak.

4. Clean the dirt in this area with water. Dry the area with an air hose.

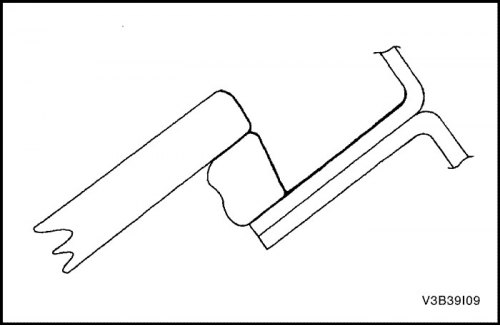

5. With a sharp knife, cut off the uneven edges of the adhesive putty around the leak at a distance of 75 to 100 mm (3 to 4 inches) on both sides of the leak.

6. With a sharp knife, cut off the uneven edges of the adhesive material around the leak at a distance of 75 to 100 mm (3 to 4 inches) on both sides of the leak.

7. Prime the cut area with a primer.

8. Allow primer to dry for 5 minutes.

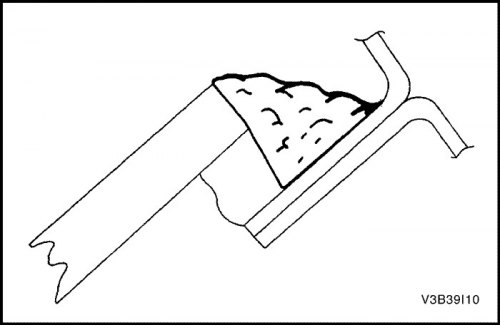

9. Apply adhesive to the leak and at a distance of 75 to 100 mm (3 to 4 inches) on both sides of the leak.

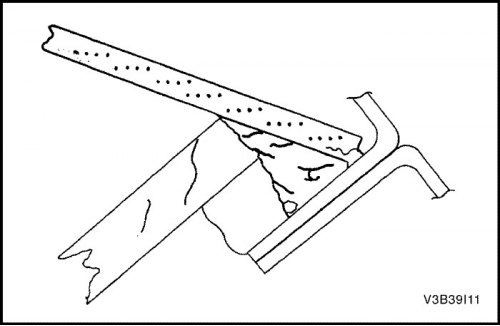

10. Immediately after applying the adhesive, use a flat stick or similar tool to ensure that the adhesive penetrates into the leak area and into the joints between the original material and the car body to ensure tightness.

11. Spray warm or hot water on the repaired area to determine if the leak has been fixed. Do not direct high pressure water jet at freshly applied adhesive.

12. Install trim panels, if removed.

13. Install decorative molding, if removed.

14. Install protective molding.

Important: Once the water leak has been repaired, re-test with water test benches. Do not conduct localized tests on freshly repaired areas as the repair material may be dislodged by unnatural pressure.