2. Disconnect the electrical connector for the heated glass in the tailgate.

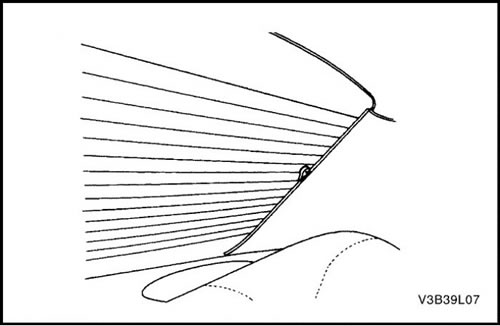

3. Inspect the lines of the heating screen of the tailgate glass.

4. Mark the place where the grid line breaks on the outside of the glass with a wax pencil or chalk.

5. Clean the mesh lines to be repaired with steel wool. Wipe the lines clean with a cloth dampened with alcohol. Strip and peel approx. 6 mm (0.25 inch) on each side of the grid line break.

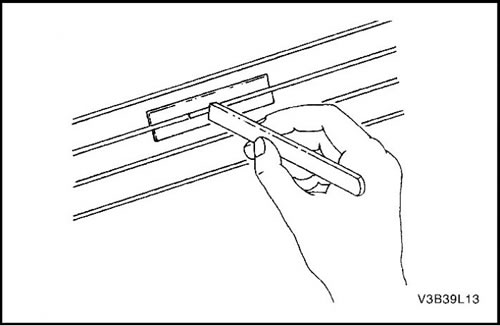

6. Apply a repair stencil or two strips of tape above and below the repair.

- A repair stencil or tape should be used to control the width of the repair.

- If a stencil is used, the slot cut must be the same width as the grid line.

7. Apply the mesh repair material to the repair site using a small wooden stick or spatula. The restorative mesh material should be at room temperature.

8. Carefully remove the stencil or tape.

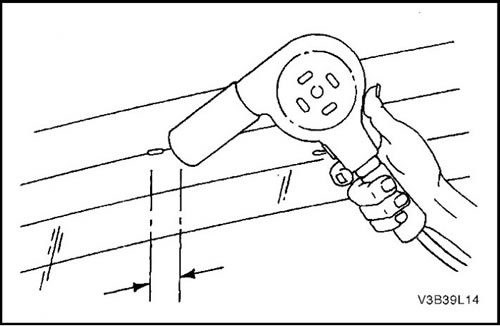

Note: Restorative material for mesh lines must be hot cured. To prevent damage to the interior finish from radiant heat, the finish at the heat treatment site must be protected.

9. Heat the repair site for 1-2 minutes.

10. Keep the nozzle of the jet dryer at a distance of 25 mm (1 inch) from the surface. Requires a temperature of at least 149°C (300°F).

11. Inspect the grid line repair site. If discoloration is observed at the repair site, apply iodine solution to the area using a pipe cleaner or a straight brush. Let the iodine dry for 30 seconds. Gently wipe off excess iodine with a lint-free cloth.

12. Check the operation of the heated rear window and verify that the repair was successful.

Important: It takes at least 24 hours for the restorative materials to fully cure. Until this time has elapsed, the repair site should not be subjected to physical impact.