For replacement of oil seals of internal constant velocity joints (SHRUS) drain the oil from the gearbox (see «Checking the level, topping up and changing the oil in a manual transmission»).

NOTES: The inner CV joint seals can be replaced without removing the transmission from the vehicle.

1. Place the vehicle on a pit or lift.

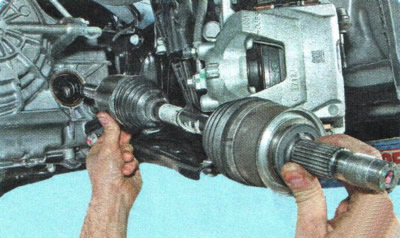

2. To replace the inner joint oil seal, remove the wheel drive from the side of the oil seal being replaced (see «Removal and installation of front wheel drives»).

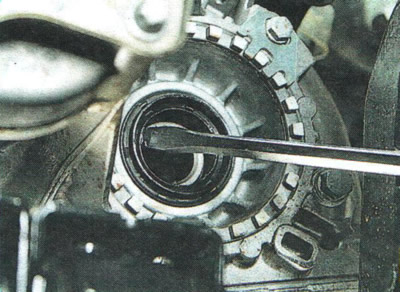

3. Remove the oil seal with a screwdriver.

4. Lubricate the seal lip with gear grease and press it with a mandrel of suitable diameter with the seal lip inside the box.

5. Similarly replace the second epiploon.

6. Install the removed parts in the reverse order of removal.

The reason for oiling the clutch disc of a car with a manual transmission may be a leak in the gearbox input shaft oil seal or the crankshaft rear oil seal.

Motor and transmission oils have different smells. Therefore, using it, having a certain skill, you can determine which oil seal is defective: the input shaft oil seal or the crankshaft rear oil seal.

GOOD ADVICE: There is another way to determine the type of oil. Drop oil into water poured into a vessel in a thin layer (maybe in a puddle). The gear oil will spread over the entire surface of the water in the form of an iridescent film, and the engine oil will remain in the form of a drop, similar to a lentil grain.

To replace the input shaft seal, the gearbox must be removed from the vehicle (see «Removal and installation of a manual transmission»).

You will need: the same tools as for replacing the clutch release slave cylinder with the clutch release bearing (see «Replacement of the working cylinder of the clutch release actuator with the clutch release bearing»), as well as the key «on 10», screwdriver.

1. Remove the clutch release slave cylinder with the clutch release bearing (see «Replacement of the working cylinder of the clutch release actuator with the clutch release bearing»).

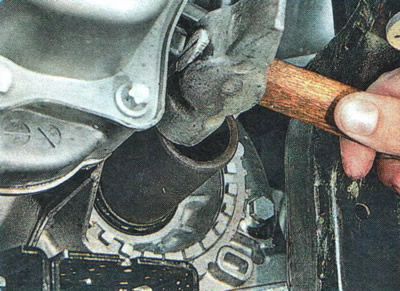

2. Remove the oil seal from the body of the working cylinder with a screwdriver.

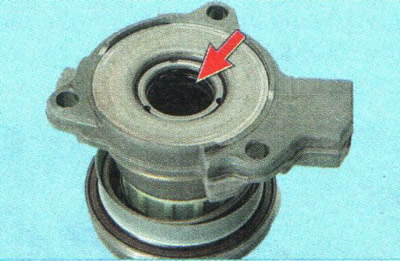

3. Lubricate the sealing lip with gear oil and press it into the working cylinder body with a mandrel of suitable diameter, orienting it so that when installing the cylinder, the sealing lip is directed inside the gearbox.

4. Install the parts in the reverse order of removal.