The front wheel drives are removed for replacement if damaged or to replace the hinges and their covers. In addition, the front wheel drives may need to be removed to gain access to other units.

NOTE: The removal and installation procedure is shown using the left front wheel drive as an example. The right wheel drive is removed and installed in the same way.

1. Remove the mudguards and crankcase protection, if installed on the car (see «Removal and installation of mudguards and engine crankcase protection»).

2. Drain the oil from the manual transmission (see «Checking the level, topping up and changing the oil in a manual transmission») or working fluid from an automatic transmission (see «Checking the level, topping up and replacing the working fluid in an automatic transmission»).

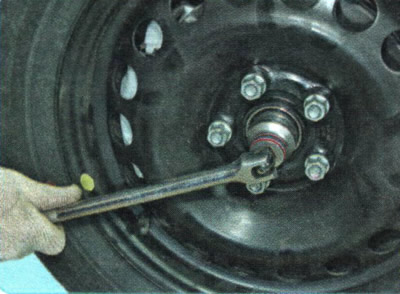

3. If stamped steel wheels are installed on the car, remove the decorative wheel cap, straighten the jammed edge of the shoulder of the front hub nut with a thin chisel and hammer...

4....and loosen the hub nut...

5.... and wheel nuts.

WARNING: Loosen and tighten the hub nut and wheel nuts only with the vehicle on the ground.

6. Raise the front of the vehicle and secure it on jack stands.

NOTE: If the vehicle is fitted with alloy wheels, the center portion of the wheel hub will block access to the hub nut. In this case, first remove the wheel and loosen the hub nut, keeping the hub from turning with a mounting spatula, resting it on the two wheel nuts screwed onto the hub studs.

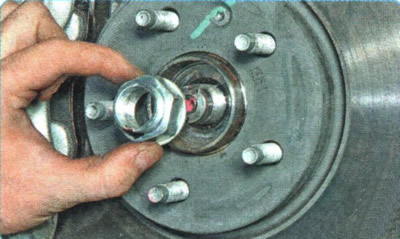

7. Completely unscrew the hub nut and remove the wheel.

NOTE: Be sure to replace the hub nut with a new one.

8. Disconnect the tie rod end from the steering knuckle (see «Replacing the outer tie rod end»).

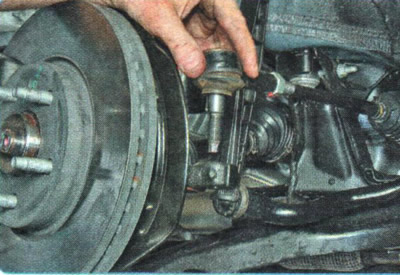

9. Turn away a nut of a coupling bolt of fastening of a finger of a spherical support to a rotary fist...

10.... and remove the bolt.

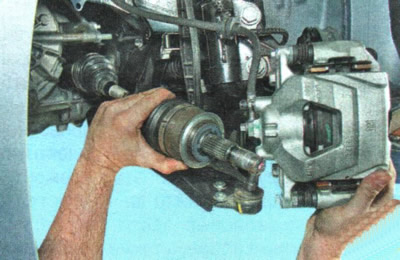

11. Pressing down the front suspension arm...

12.... take aside the steering knuckle assembly with the shock absorber strut and remove the splined shank of the outer constant-velocity joint of the front wheel drive from the hub.

USEFUL ADVICE: If you cannot remove the pivot shank with your hands, knock it out of the hub with light hammer blows through a spacer made of soft metal or wood.

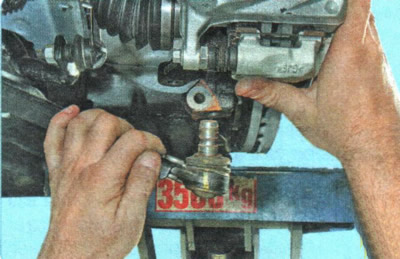

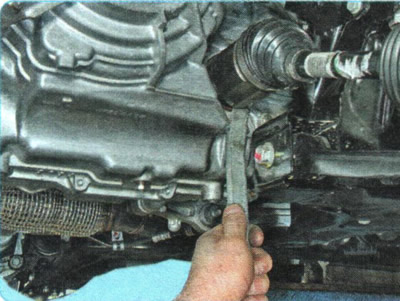

13. Using a mounting spatula, press out the shank of the internal drive joint from the gear of the differential axle shaft...

NOTE: The gap between the inboard joint housing and the gearbox housing is very small so it is not possible to fully insert the end of the spudger into it all at once. Having inserted the pointed part of the mounting blade into the gap, with gentle blows of the hammer along the blade, drive its end deep into the gap, pushing the hinge body away from the crankcase like a wedge until the retaining ring of the hinge shank comes out of the axle gear. Then finally push the hinge shank out of the gear with a spatula.

WARNING: When using a spudger to remove the inner joint from the transaxle pinion, be careful not to damage the transaxle case and joint.

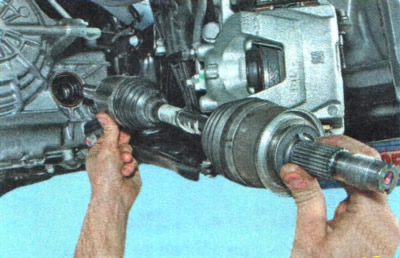

14.... and remove the left front wheel drive assembly.

WARNING: Replace the drive inner joint shank circlip with a new one each time the drive is removed from the vehicle, otherwise the drive may spontaneously pop out of the side gear while driving.

15. Remove the right front wheel drive in the same way.

16. To install the drive, first insert the splined shank of the outer joint housing into the wheel hub and screw the hub nut until it stops without fully tightening it.

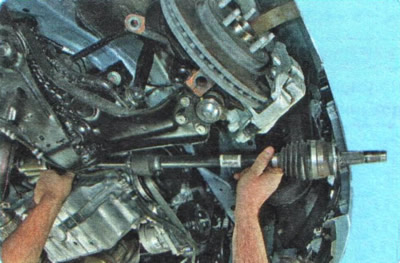

17. Then insert the splined shank of the inner joint housing into the axle shaft seal and turn the drive shaft slightly so that the splines of the joint shank and the axle gear are aligned.

18. Pull the front suspension arm down and with a sharp movement of the shock absorber strut with the steering knuckle, press the drive into the axle shaft gear until the drive is fixed with the retaining ring.

19. Attach the shock absorber ball joint to the lower arm.

20. Attach the tie rod to the steering knuckle.

21. Establish a wheel and wrap nuts of its fastening against the stop, without tightening them finally.

22. Having removed from supports, establish the car on wheels, and tighten a nut of a nave the moment of 250 Нм.

23. Lock the hub nut by tapping the edge of its shoulder with a beard and hammer into the groove on the shank of the outer hinge housing.

NOTE: The hub nut on a vehicle equipped with alloy wheels must be tightened and locked completely before the wheel is installed, keeping the hub from turning as was done when unscrewing it (see note).

24. Tighten the wheel nuts (see «Wheel replacement»).

25. Fill the oil in the manual transmission (see «Checking the level, topping up and changing the oil in a manual transmission») or working fluid in an automatic transmission (see «Checking the level, topping up and replacing the working fluid in an automatic transmission»).

26. Install mudguard and crankcase protection (see «Removal and installation of mudguards and engine crankcase protection»).