If engine power drops, increased noise occurs, or howls are heard periodically when the fuel pump is operating, then the fuel module is most likely faulty. Pre-check the pressure in the fuel supply system (see «Checking the pressure in the power system»). If the pressure in the system is less than 380 kPa, then the fuel pressure regulator, the electric fuel pump itself, or the fuel filter are probably clogged. To eliminate these faults, the fuel module must be replaced as an assembly, since its design is not separable. It is only possible to replace the fuel gauge sensor.

1. Reduce the pressure in the supply system (see «Reducing the pressure in the power system»).

2. Disconnect the wire from the terminal «minus» battery.

3. Remove the fuel tank (see «Replacing the fuel tank and its filler pipe»).

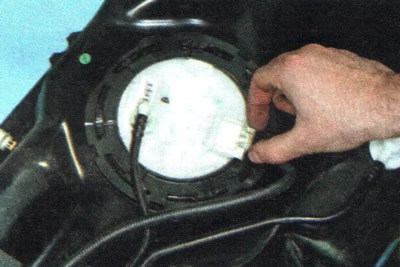

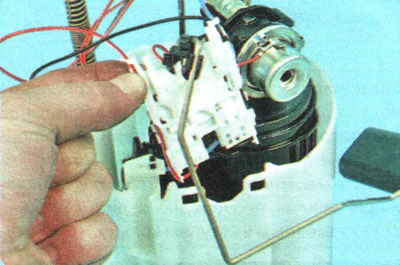

4. Pull out the locking bracket...

5.... and disconnect the wiring harness block from the fuel module.

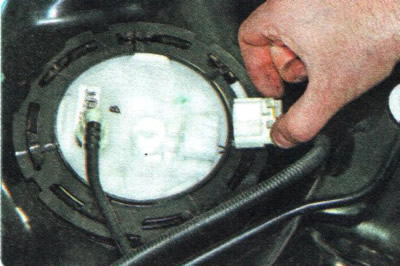

6. Pressing the latch...

7.... disconnect the high pressure fuel line tip from the module fitting.

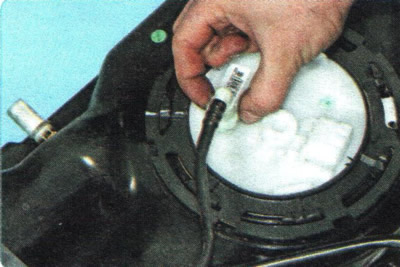

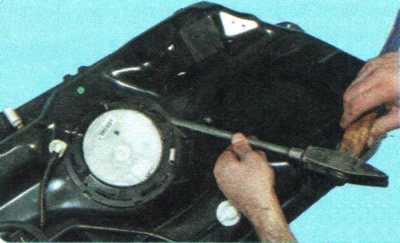

8. Turn counterclockwise the clamping ring of the fuel pump module bayonet mount until the protrusions of the ring come out from under the fuel tank flange clamps...

NOTE: There is a tool to rotate the fuel pump module mounting clamp. In the absence of this device, remove the ring from its place with light hammer blows through a screwdriver, applying force alternately to the diametrically located protrusions of the ring.

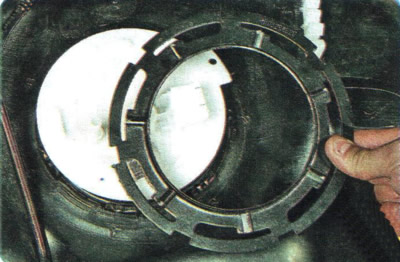

9.... and remove the ring.

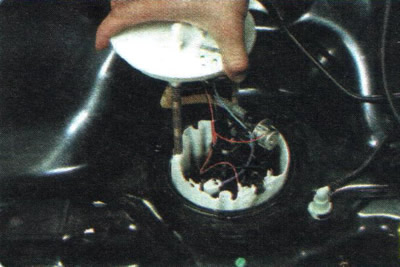

10. Remembering the position of the adapter flange of the fuel pump module relative to the fuel tank (to facilitate its installation during re-assembly), remove the flange, carefully remove the module and drain the fuel from it into a previously prepared container.

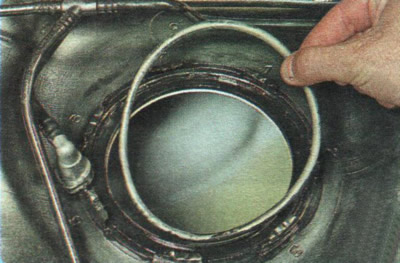

NOTE: The fuel module adapter flange is sealed with a rubber o-ring.

Be sure to replace this ring each time the pump is removed.

11. If necessary, remove the fuel gauge sensor from the fuel module (see «Replacing the fuel gauge sensor»).

12. Install the parts in the reverse order of removal.