Signs of an incompletely closing throttle valve may include increased idling speed and fuel consumption; if the throttle valve is not fully opened, the engine does not develop full power, is not throttled enough, jerks and dips are observed in its operation when the car is moving. Throttle valve fouling from blow-by deposits usually results in erratic idling. The throttle valve drive is electric, it is controlled by the electronic unit of the engine management system. Repairing an electric drive requires qualified personnel and special equipment. Therefore, with these malfunctions, first try flushing the throttle (e.g. thinner or special aerosol carburettor cleaner). If this does not lead to a positive result, replace the throttle assembly.

1. Disconnect the wire from the terminal «minus» battery.

2. Drain the liquid from the engine cooling system (see «Coolant replacement»).

NOTE: With a known skill, the coolant can not be drained. Have suitable plugs ready to plug the hoses immediately after disconnecting them. The loss of coolant with this method will be negligible.

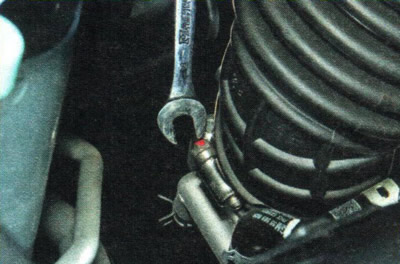

3. Loosen the clamp that secures the air supply hose to the nozzle of the throttle assembly and remove the hose from the nozzle.

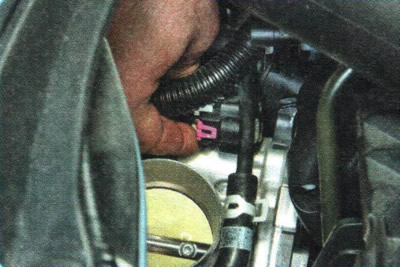

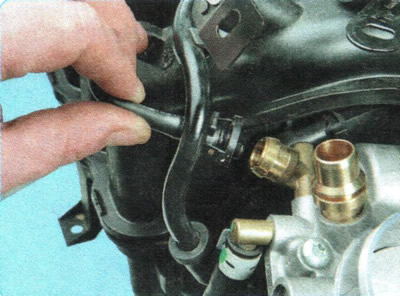

4. Move the spring retainer of the hose end of the crankcase ventilation system...

5.... and disconnect the hose from the nozzle of the throttle assembly.

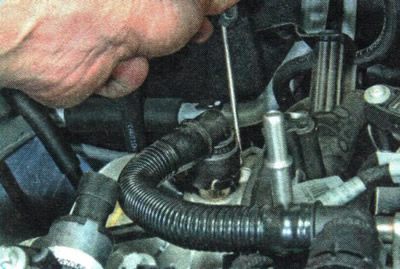

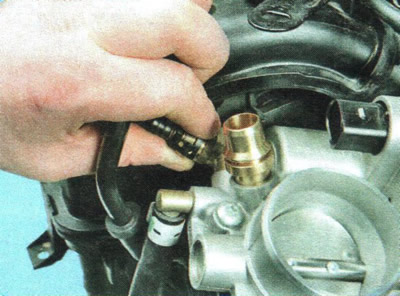

6. Slide stop...

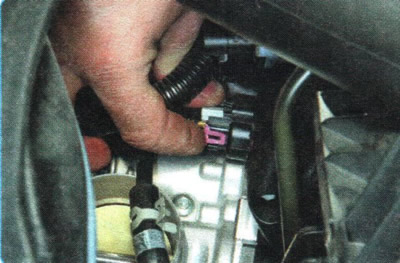

7.... then squeeze the clamp of the wiring harness block...

8.... and disconnect the block from the throttle assembly.

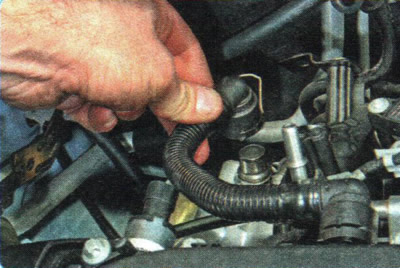

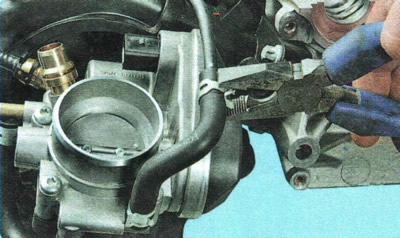

9. Loosen the hose clamp for the coolant drain hose...

NOTE: For clarity, operation here and below is shown with the cylinder head removed.

10.... and disconnect the hose from the intermediate tube.

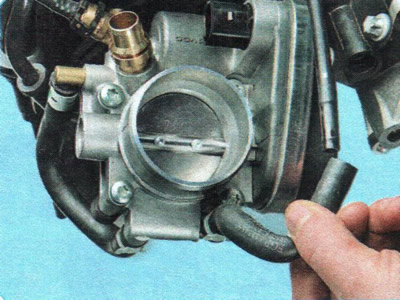

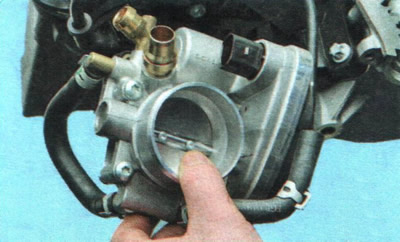

11. Squeeze the retainer of the coolant hose tip...

12.... and disconnect the hose from the nozzle of the throttle assembly.

NOTE: If you have not drained the cooling system, plug the hoses immediately with pre-prepared plugs or appropriately sized bolts to prevent loss of fluid.

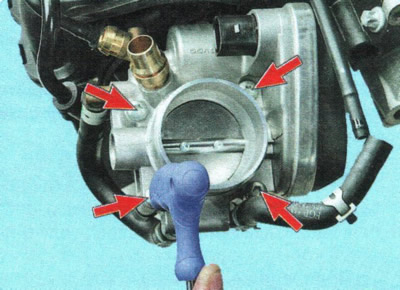

13. Turn out four bolts of fastening of a throttle knot to an inlet pipe...

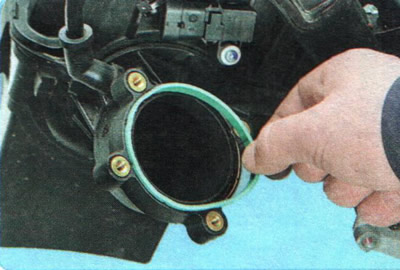

14.... remove the throttle assembly...

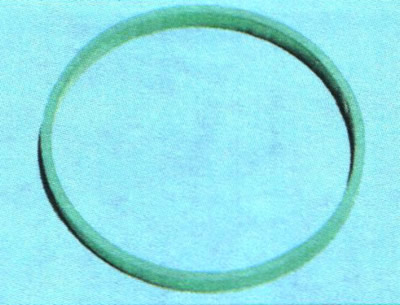

15.... and the sealing ring installed under its flange.

NOTE: Replace the throttle assembly flange o-ring each time the joint is disassembled.

16. If the throttle assembly was not removed for replacement, clean the contaminated throttle assembly with carburetor cleaner.

17. Remove oil and other contaminants from the cavity of the inlet pipe.

18. Install the throttle assembly in the reverse order of removal.