The oil sump flange is mounted on sealant, there is no gasket. Therefore, if there is an oil leak in the connector of the oil sump and the cylinder block, tightening the oil sump mounting bolts will not lead to the desired result. Remove the oil pan and replace its seal.

1. Place the vehicle on a lift or pit.

2. Drain the engine oil.

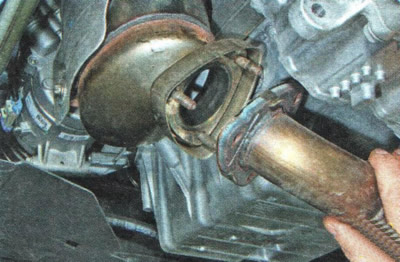

3. Remove the front pipe of the exhaust system (see «Downpipe replacement»).

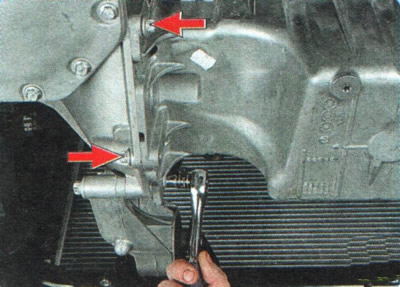

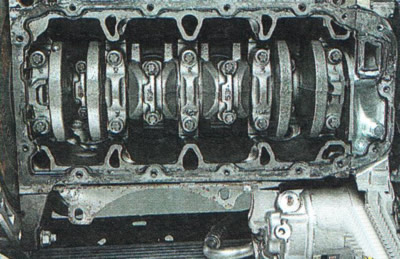

4. Remove the three bolts securing the oil sump to the clutch housing...

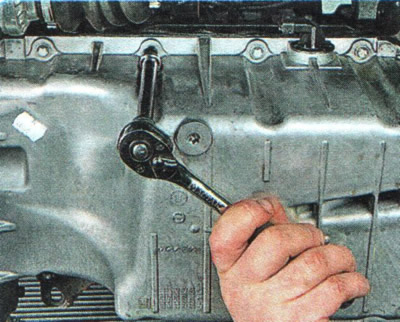

5.... bolts for fastening the oil sump to the cylinder block...

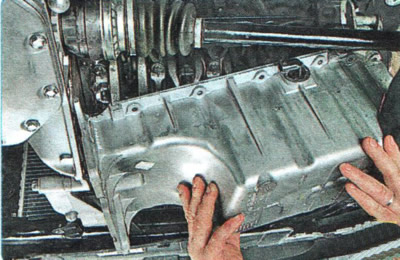

6.... and remove the crankcase.

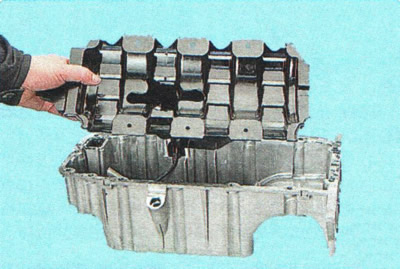

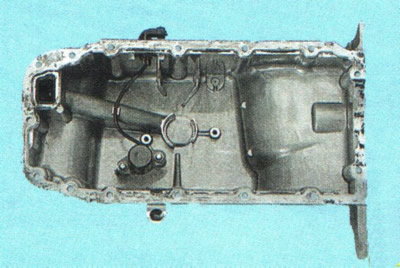

7. If necessary, remove the oil deflector by unscrewing the bolts securing the shield to the oil sump...

8.... and remove the shield.

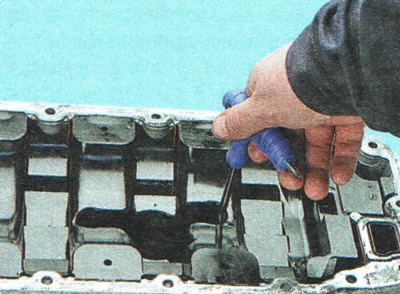

9. Clean the mating surfaces of the cylinder block from the old sealant...

10.... and oil sump.

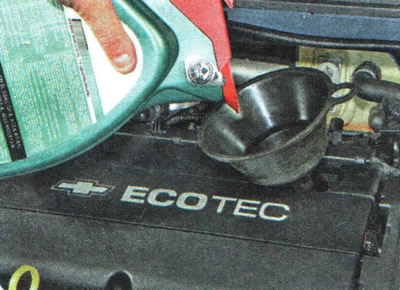

11. Apply special sealant to the mating surface of the oil pan (MS 721-40A or equivalent) roller with a diameter of 4 mm, and the sealant application line must pass from the inside of the mounting holes.

12. 5 minutes after applying the sealant, install the oil crankcase on the cylinder block, screw in the crankcase mounting bolts and tighten them to the torque specified in Appendix 1.

13. Establish all removed details and knots in an order, the return to removal.

14. Fill engine oil (see «Changing engine oil and oil filter»).

NOTE: You can fill in oil and start the engine no earlier than half an hour after installing the oil sump, this time is necessary for the polymerization of the sealant.