...a valve spring compressor...

...tick...

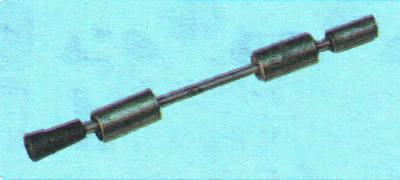

...or an inertial oil seal remover. At the other end of the shown puller there is a mandrel for pressing on the caps. In the absence of such a puller, you will need pliers to remove the caps and a mandrel of a suitable diameter to press them onto the valve guides.

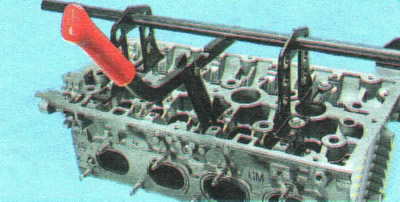

An external sign of wear on the valve stem seals is the short-term appearance of blue smoke from the exhaust pipe after starting the engine and when braking the engine after a long drive under load. Moreover, constant smoking is usually not observed. Indirect signs are increased oil consumption in the absence of external leaks and oily spark plug electrodes.

1. Remove the cylinder head (see «Replacing the cylinder head gasket»).

2. Remove the valve lifters.

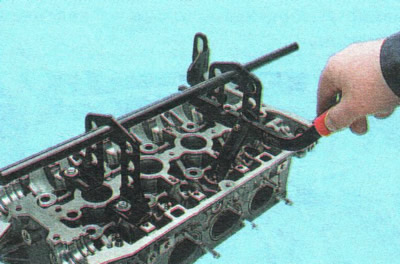

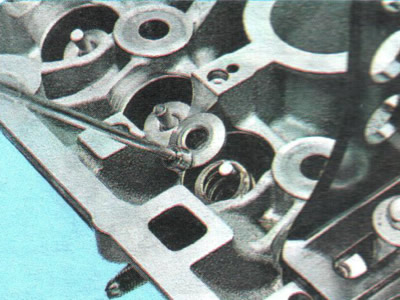

3. Install the valve spring compressor on the cylinder head.

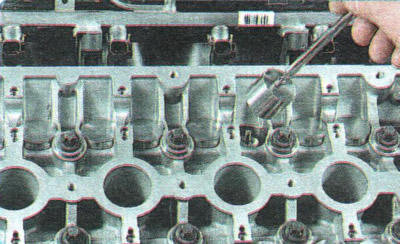

4. Compress the spring of one of the valves with the tool and remove two crackers from the spring plate using tweezers or a magnetized screwdriver.

USEFUL ADVICE: If the force of moving the lever of the device increases significantly, and the crackers do not come out of the valve groove, apply a light blow with a hammer on the spring plate to release the crackers.

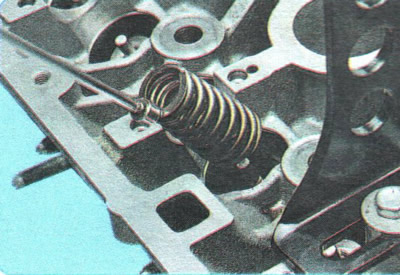

5. Remove the spring plate...

6.... and valve spring.

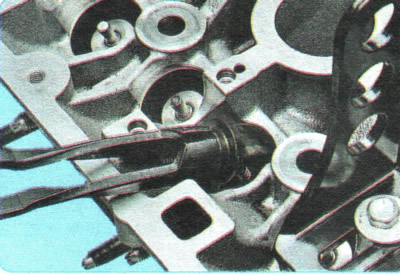

7. Press the valve stem seal off the valve guide. To do this, install the collet of the inertial oil seal remover on the cap and sharply hit the collet bushing with the striker. Then just as sharply hit the handle of the device with the striker, thereby compressing the cap from the sleeve.

8. In the absence of an inertial cap remover, remove the cap with a special tong-type remover or pliers, applying force straight up and without turning the cap so as not to damage the valve guide.

WARNING: Do not remove the cap by prying it on both sides with screwdrivers. The guide sleeve, on which the cap is put on, is made of cermet, and its edge easily breaks off.

9. Lubricate the inner surface of the valve stem seal with engine oil and slide the cap over the valve stem to the guide sleeve.

10. Install the mandrel for pressing the cap. With light blows of the striker on the mandrel, press the cap in until it stops. In the absence of a special device, you can choose a cylindrical mandrel of a suitable diameter and press the cap through it with light hammer blows on the mandrel.

11. Install the spring and valve disc in the reverse order of removal. Install the crackers with the tool so that they fit into the grooves of the valve stem. After installing the crackers, hit the end of the valve with a hammer through the metal rod so that the crackers sit in place.

WARNING: If the skewed cotters remain loose when starting the engine «cracked» the valve will fall into the cylinder, resulting in a serious engine failure.

12. Similarly replace valve stem seals of other valves of a head of the block of cylinders.

13. Install the removed parts in the reverse order of removal. After installing the camshafts and the timing belt, check and, if necessary, adjust the clearances in the valve drive, see. «Valve clearance adjustment»).