The manufacturer recommends removing the power unit (engine with gearbox) down. This requires a lift to raise the front of the car higher. In a garage environment without a lift, you will need a jack, as well as strong and high enough supports to support the raised front of the car on them. This will make it possible to remove the engine from under it, lowered to the garage floor.

GOOD ADVICE: The engine is very heavy, so we recommend that you remove it with an assistant and use special equipment (lift, hoist, etc.).

WARNING: When removing and installing a power unit assembly with a large mass, use only fully serviceable lifting mechanisms designed for the appropriate load, and especially carefully control the correctness and reliability of connecting cables, traverses, etc. to the transport eyes of the engine.

1. Remove the battery.

2. Remove the battery mounting shelf (see «Removal and installation of the shelf of fastening of the rechargeable battery»).

3. Drain engine oil (see «Changing engine oil and oil filter»).

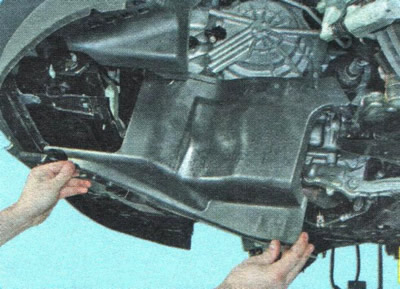

4. Remove mudguards and crankcase protection (see «Removal and installation of mudguards and engine crankcase protection»).

5. Drain the cooling system (see «Coolant replacement»).

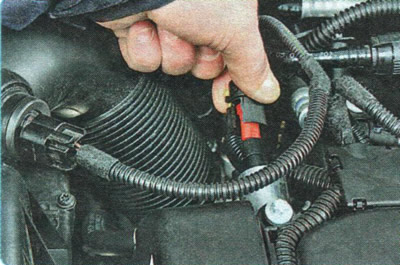

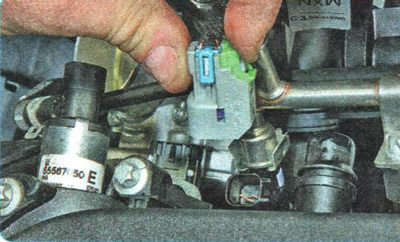

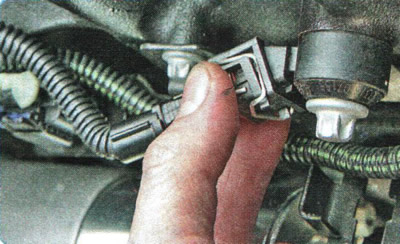

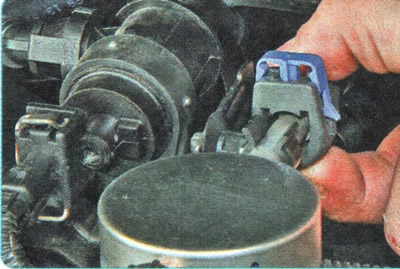

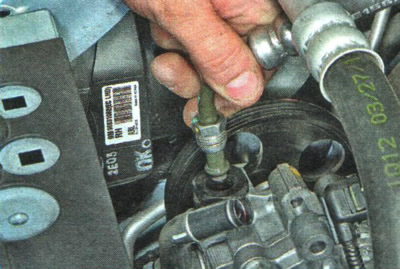

6. Press the latch...

7.... and disconnect the wiring harness connector from the electro-hydraulic valve of the exhaust camshaft.

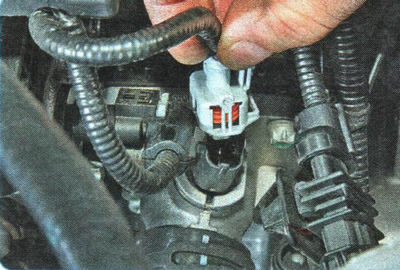

8. Disconnect the wiring harness connector from the electro-hydraulic valve of the intake camshaft in the same way.

9. Remove the air filter (see «Removal and installation of the air filter and an air duct»).

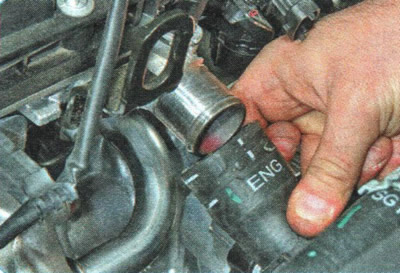

10. Press the latch and disconnect the wiring harness block from the thermostat heating element.

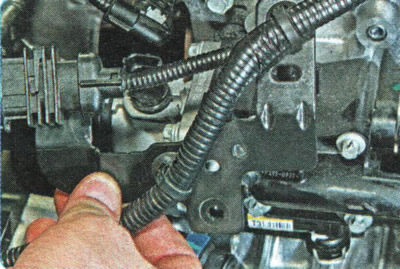

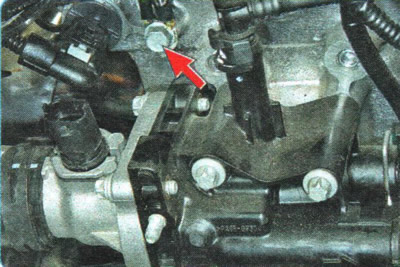

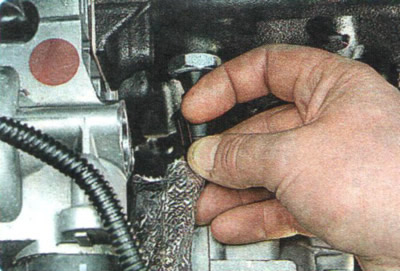

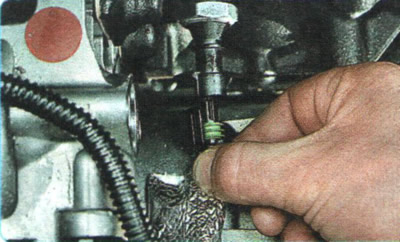

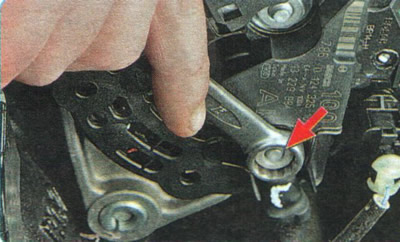

11. Turn away a nut of fastening of an arm of a plait of wires of a motor compartment.

12. Remove the bracket from the stud and move the wiring harness to the side.

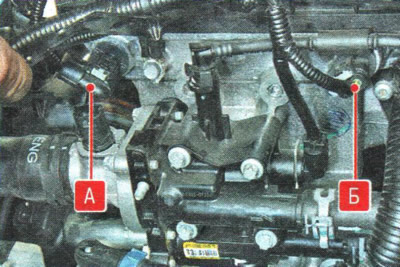

13. Disconnect the wiring harness pads from the exhaust camshaft position sensor A and from the intake camshaft position sensor B.

14. Disconnect the wiring harness connectors from the fuel injectors.

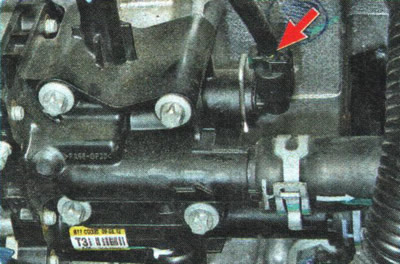

15. Turn out a bolt of fastening of a tip of a wire «minus» to the cylinder head and move the tip to the side.

16. Press a clamp and disconnect a block of a plait of wires from the gauge of temperature of a cooling liquid.

17. Disconnect the wiring harness connector from the knock sensor.

18. Loosen the heater hose clamps by squeezing their bent antennae with pliers. Slide the hose clamps...

19.... and disconnect the hoses from the nozzles.

20. Similarly, loosen the hose clamp to the thermostat nozzle and disconnect the hose from the nozzle.

21. Loosen the brake booster vacuum hose clamp by squeezing its bent antennae with pliers. Slide the clamp over the hose and disconnect the hose from the inlet pipe fitting.

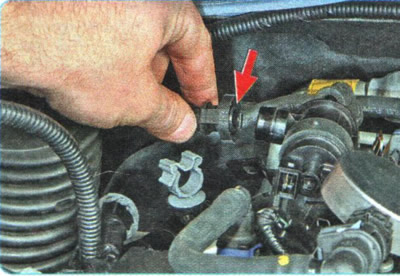

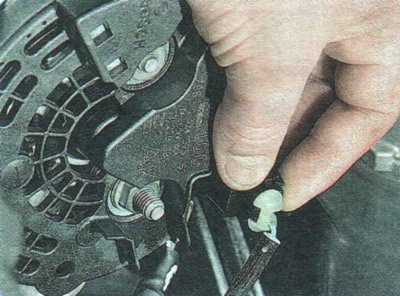

22. Pry with a screwdriver, pull out the plastic retainer...

23.... press the stopper and disconnect the tip of the fuel hose from the pulsation compensator.

24. Slide the heat shield over the wiring harness.

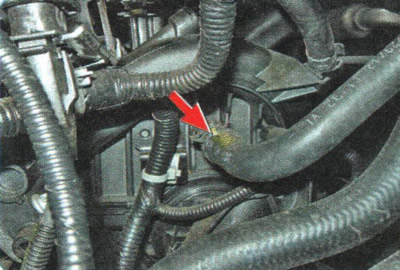

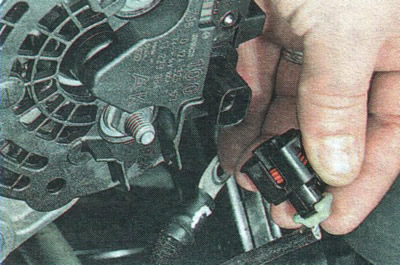

25. Press the clamp of the wiring harness block...

26.... and disconnect the block from the oil pressure sensor.

27. Disconnect the plastic holders of the engine wiring harness from the engine brackets by biting them with wire cutters.

28. Remove the wiring harness from the engine compartment.

29. Squeeze the bent ears of the clamp that secures the outlet hose of the radiator to the water pump pipe, slide the clamp along the hose...

30.... and remove the nozzle hose.

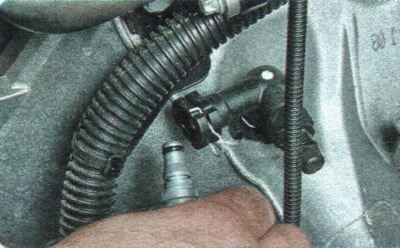

31. Squeeze the latch on the steam line tip and disconnect the tip from the canister purge valve fitting.

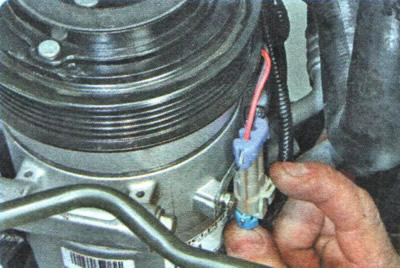

32. Press the clamp of the wiring harness block...

33.... and disconnect the block from the connector of the electromagnetic clutch of the air conditioning compressor.

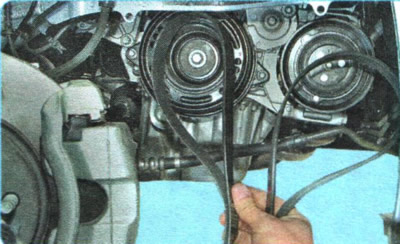

34. Remove the accessory drive belts (see «Replacing accessory drive belts»).

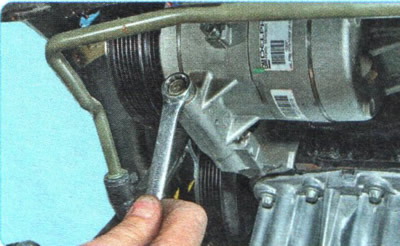

35. Turn out bolts of fastening of the compressor of the conditioner, take the compressor aside, without disconnecting hoses from it, and fix the compressor on a body with a wire, without allowing twisting or a tension of hoses.

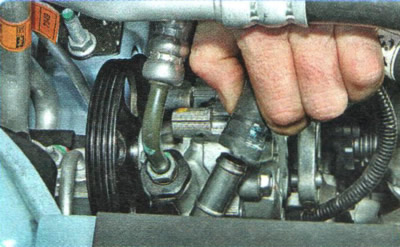

36. Disconnect the return valve from the power steering pump...

37.... and pressure pipes (see «Removal and installation of the power steering pump»).

38. Turn away a nut of fastening of a tip of a power wire and disconnect a wire from an output of the generator.

39. Press the retainer of the voltage regulator wiring harness block...

40....and disconnect the block from the regulator.

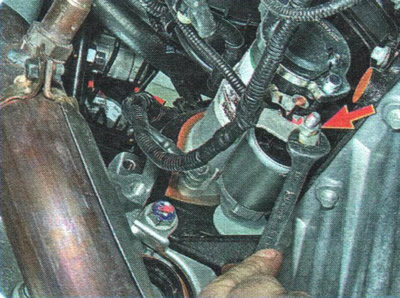

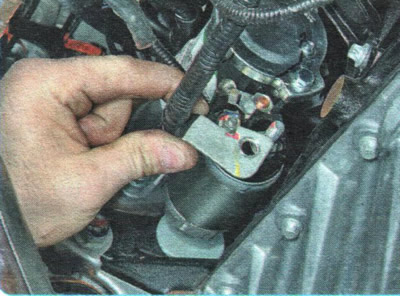

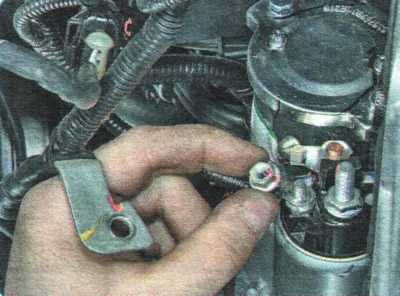

41. Unscrew the nut of the power wire...

42.... and remove the wire from the contact bolt of the traction relay.

43. Turn away a nut of fastening of a control wire of the traction relay.

44. Remove the control wire from the contact bolt of the traction relay and take the removed wires to the side.

45. Loosen the fastening nut «mass» wires.

46. Remove «mass» wire from the bottom stud of the starter and take it to the side.

47. Disconnect the control cables and sensor wiring harness blocks from the gearbox (see «Removal and installation of a manual transmission» or «Removal and installation of an automatic transmission»).

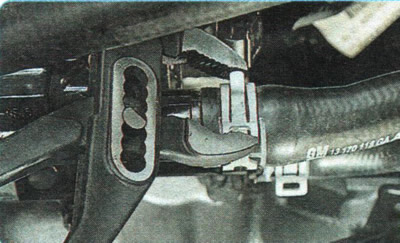

48. On a car with a manual transmission, pry with a screwdriver...

49.... pull the retainer out of the clutch release pipeline adapter...

50.... and remove the hose tip from the adapter.

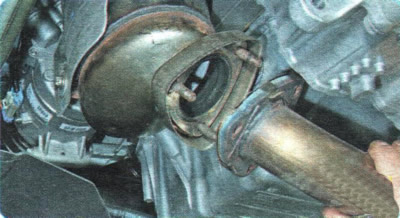

51. Remove the exhaust pipe of the exhaust system (see «Downpipe replacement»).

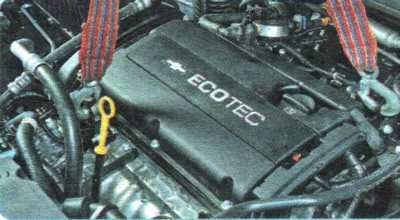

52. Sling the engine on the special eyelets and tighten the sling (e.g. crane, hoist or other lifting device).

WARNING: Make sure the sling is securely attached to the mounting lugs.

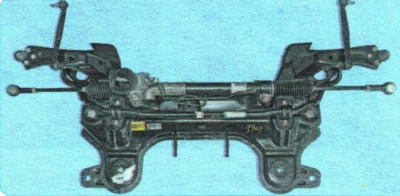

53. Remove the front suspension cross member (see «Removal and installation of a cross-beam of a forward suspension bracket»).

54. Remove the front wheel drives (see «Removal and installation of front wheel drives»).

55. Place reliable supports under the power unit (it is best to use a rolling cart with a load capacity of at least 300 kg).

56. Lower the front of the vehicle so that the power unit rests on a support or cart.

57. Check if all wires attached to the body are disconnected from the power unit. Check if hoses, tubes and body components interfere with the removal of the power unit down.

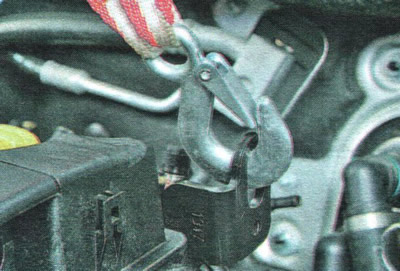

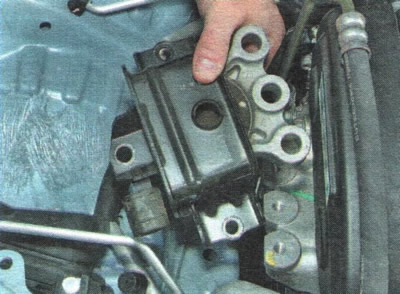

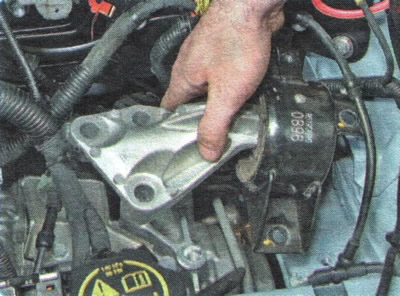

58. Remove the right...

59.... and the left suspension mount of the power unit (see «Replacing the suspension bearings of the power unit»).

60. Hang the front of the car (raise the car on a lift) to a height sufficient to remove the power unit from under the vehicle, and place reliable supports under the body.

61. Remove the power unit from under the car.

62. Establish the power unit, and also all removed knots and details in sequence, return to removal. When connecting wires and pipelines, carefully monitor their correct location in the engine compartment, avoiding contact with heating and moving elements of the power unit.

63. Fill the engine with oil (see «Changing engine oil and oil filter»).

64. Fill with coolant (see «Coolant replacement»).

65. On a car with a manual transmission, bleed the air from the hydraulic clutch release (see «Bleeding the hydraulic clutch release»).

66. Start the engine and check for fuel, oil and coolant leaks. Check oil pressure. Listen to the engine: it should run smoothly, without extraneous noise and knocks.