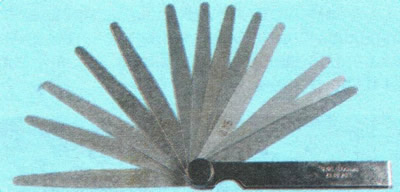

...and a set of measuring probes.

To compensate for the thermal expansion of the valve, a gap is set between the end of the valve stem and the camshaft cam. With an increased clearance, the valve will not open fully, and with a reduced clearance, it will close completely.

The gap is measured with a feeler gauge when cold (at +20°C) engine between the camshafts (the cam must point away from the pusher) and the end surface of the valve lifter.

For a cold engine, the nominal intake camshaft clearance is (0,25±0,04) mm, on the exhaust shaft - (0,30±0,04) mm.

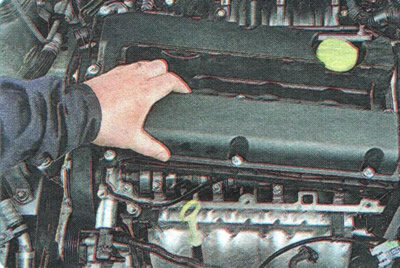

1. Remove the cylinder head cover (see «Replacing the cylinder head cover gasket»).

2. Set the piston of the 1st cylinder to the TDC position of the compression stroke (see «Setting the piston of the first cylinder to the TDC position of the compression stroke»). In this case, the cams of the intake valves of the 2nd cylinder and the exhaust valves of the 3rd cylinder should be directed upwards and located symmetrically at a slight angle inward (to the center of the block head).

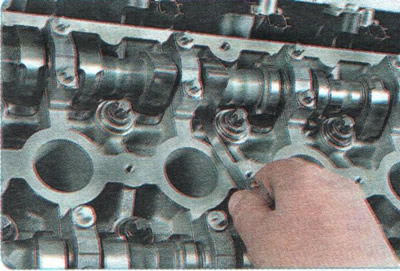

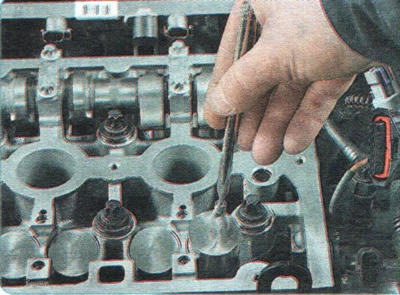

3. Measure the gaps with a feeler gauge. If the gaps are out of specification, use feeler gauges to determine the actual gap and record the values. Similarly, measure the clearances in the remaining valves. To do this, do the following:

- turn the crankshaft half a turn. In this position, check the clearances on the cams of the inlet valves of the 1st cylinder and the exhaust valves of the 4th cylinder;

- again turn the crankshaft half a turn. In this position, check the gap on the cams of the inlet valves of the 3rd cylinder and the exhaust valves of the 2nd cylinder;

- turn the crankshaft another half turn and check the clearance on the cams of the inlet valves of the 4th cylinder and the exhaust valves of the 1st cylinder.

4. If the clearances in the valve drive are not correct, adjust the clearances. To do this, it is necessary to replace the tappets of those valves whose clearances differ from the nominal values.

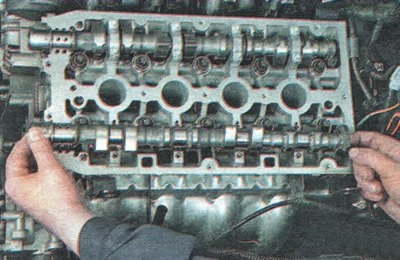

5. Remove the corresponding camshaft (see «Removal, troubleshooting and installation of camshafts»).

6. Remove the valve lifters.

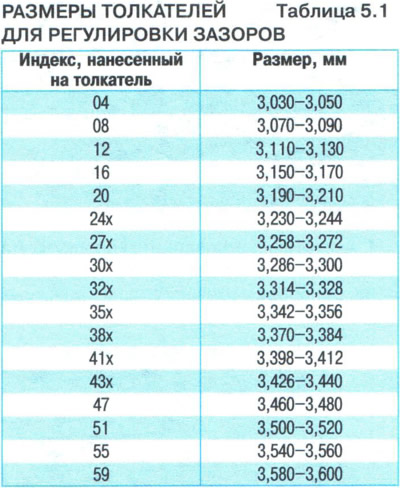

7. An index is applied to the inside of the pusher, which corresponds to a certain thickness of the bottom of the pusher (tab. 5.1). Calculate the size of the adjusting pusher N using the formula N = T + A - S (all dimensions in mm), where T is the size of the removed pusher; A - measured clearance in the valve; S - nominal clearance.

8. Install the valve lifters with the dimensions calculated according to the formula and all removed parts in the reverse order of removal, check the clearances. Repeat the steps above if necessary.