...or manual valve holder.

The valves are lapped on the removed cylinder head. To remove the valves from the guide bushings of the cylinder head, it is necessary to remove the valve springs by compressing them with a special tool and removing crackers from the spring plates (see «Replacement of valve stem seals»).

1. Clean the valve from carbon deposits.

2. Apply a thin, continuous layer of lapping paste to the valve face.

3. Place a pre-selected spring on the valve stem and insert the valve into the guide sleeve from the combustion chamber side, lubricating the valve stem with a layer of graphite grease.

NOTE: Graphite grease keeps the guide bushing from getting abrasive from the lapping paste into its bores, making it easier to rotate the valve during lapping.

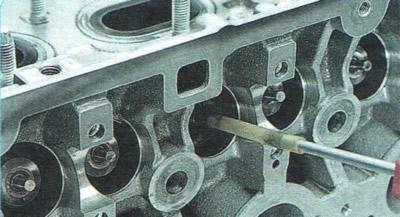

4. Place a valve lapping tool on the valve stem (or with some tightness a rubber tube to connect the valve to a reversible drill).

5. Turning on the drill at the minimum speed (in reverse mode) or rotating fixture (in case of manual lapping) alternately in both directions for half a turn, lap the valve, periodically pressing it to the seat, then loosening the pressing force.

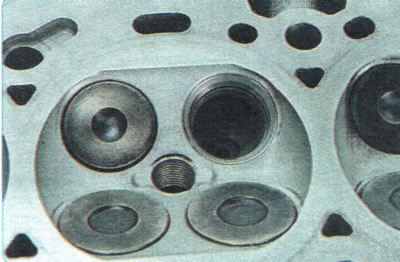

6. Grind the valve until a dull gray continuous monophonic belt appears on its chamfer, at least 1.15 mm wide for the inlet valve and 1.35 mm for the outlet valve, while...

7.... on the valve seat after grinding, a continuous monophonic belt with a width of at least 1.5 mm should also appear.

8. After lapping, thoroughly wipe the valve and seat with a clean cloth and rinse to remove any remaining lapping paste. Check the tightness of the valve, for which install it in the head with springs and crackers. Then put the head on its side and pour kerosene into the channel that is closed by the valve. If kerosene does not seep into the combustion chamber within 3 minutes, the valve is tight.

9. Lap the rest of the valves in the same way.