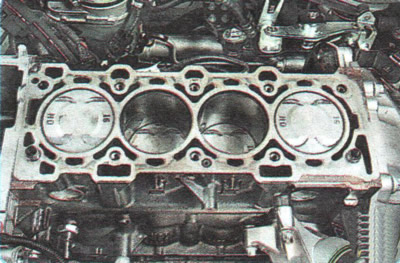

cylinder head engine is made of aluminum alloy according to the transverse cylinder purge pattern (inlet and outlet ports are located on opposite sides of the head), valve seats and valve guides are pressed into the head. Each intake and exhaust valve is equipped with one spring, fixed through the plate with two crackers.

Cylinder block engine is a single casting that forms the cylinders, the cooling jacket, the upper part of the crankcase and five crankshaft bearings made in the form of crankcase partitions. The block is made of special ductile iron with cylinders bored directly in the body of the block. Engine main bearing caps are machined complete with blocks and are therefore not interchangeable. On the cylinder block, special lugs, flanges and holes for fastening parts, assemblies and assemblies, as well as channels of the main oil line are made.

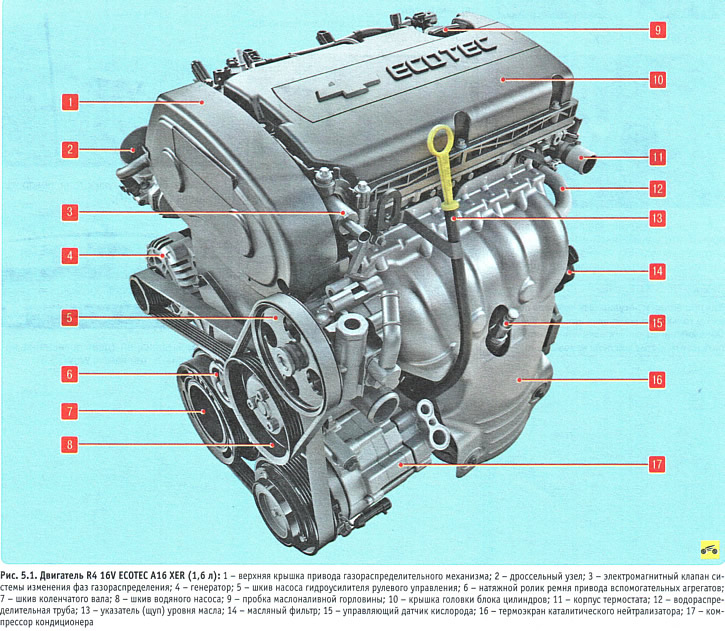

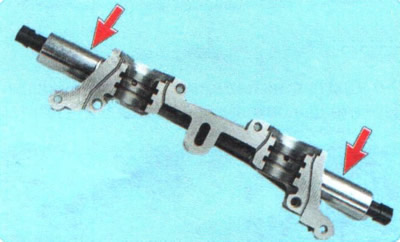

Camshafts cast, cast iron, equipped with synchronization rotors that ensure the operation of camshaft position sensors. Oil channels are made in the intake and exhaust valve drive shafts, through which oil is supplied under pressure to the mechanisms of the variable valve timing system.

Crankshaft, forged from special steel, rotates in main bearings with thin-walled steel liners with an anti-friction layer of aluminum-tin alloy. The axial movement of the crankshaft is limited by special flanges made on the middle main journal and resting on the shoulders of the thickened middle main bearing shells.

Pistons made of aluminum alloy.

On the cylindrical surface of the piston head there are annular grooves for oil scraper and compression rings. The engine pistons are additionally cooled by oil supplied through a hole in the upper head of the connecting rod and sprayed onto the piston bottom.

piston pins installed in the piston bosses with a gap and pressed with an interference fit into the upper heads of the connecting rods.

The connecting rods are steel, forged, with an I-section rod by lower heads connected to the connecting rod journals of the crankshaft through thin-walled liners.

Combined lubrication system (see more details. «Lubrication system»).

The closed-type crankcase ventilation system does not communicate directly with the atmosphere, therefore, simultaneously with the exhaustion of gases and gasoline vapors, a vacuum is formed in the crankcase under all engine operating modes, which increases the reliability of various engine seals and reduces the emission of toxic substances into the atmosphere.

Cooling system sealed engines, with an expansion tank, consists of a cooling jacket made in casting and surrounding the cylinders in the block, combustion chambers and gas channels in the cylinder head. Forced circulation of the coolant is provided by a centrifugal water pump driven by the crankshaft with a V-ribbed belt for driving auxiliary units. To maintain the normal operating temperature of the coolant, a thermostat is installed in the cooling system, which closes a large circle of the system when the engine is cold and the coolant temperature is low.

NOTE: To reduce fuel consumption and emissions during partial load operation, the Chevrolet Aveo's cooling system is equipped with a variable valve temperature thermostat. For this, a heating element is built into the thermostat housing. If the engine is running in a mode that requires more intensive cooling, the engine control unit turns on the heating element. In this case, the thermostat valve opens at a lower coolant temperature.

Supply system the engine consists of an electric fuel pump module installed in the fuel tank; throttle assembly, fuel fine filter located in the fuel module; fuel pressure regulator, injectors and fuel lines, and also includes an air filter.

Variable valve timing system dynamically adjusts the position of the intake and exhaust camshafts. This system allows you to set the optimal valve timing for each moment of engine operation, thereby achieving easy cold starting and stable operation as it warms up, increased power, better fuel efficiency and less exhaust emissions. The mechanism of the system is connected by channels in the cylinder head and in the camshafts with solenoid valves. These valves hydraulically control the variable valve timing mechanism. The solenoid valves, in turn, are controlled by the electronic engine control unit.

The solenoid valve, at the signals of the electronic engine control unit, supplies oil under pressure from the main line of the lubrication system to one of the working cavities of the mechanism of the variable valve timing system and drains the oil from the other cavity, which leads to the mutual movement of the elements of the mechanism and, as a result, to a dynamic change in the mutual position of the intake and exhaust camshafts.

While the engine is idling, the electronic engine control unit repeatedly activates the solenoid valve for short periods of time in order to clean its elements and channels from contaminants that accidentally get into them.

When the power is turned off to the electromagnetic valves of the variable valve timing system, the oil supply holes from the main line and drain are fully open and the mechanism is set to its original position. In this case, the engine operates without changing the valve timing with increased fuel consumption.