1. Open the hood and inspect the engine compartment. When inspecting the engine, pay attention to the presence of coolant in the expansion tank, the integrity of the rubber hoses, the radiator.

GOOD ADVICE: A broken hose can be temporarily repaired with adhesive tape. Reinforced adhesive tape is particularly suitable for this purpose (e.g. silver), which can be purchased at car dealerships.

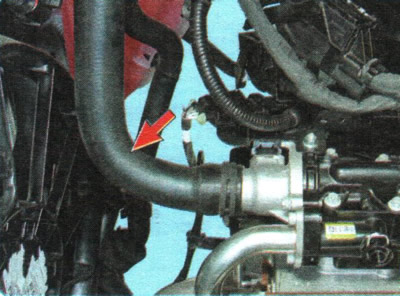

2. Inspect the connections to the supply radiator...

3.... and outlet hoses.

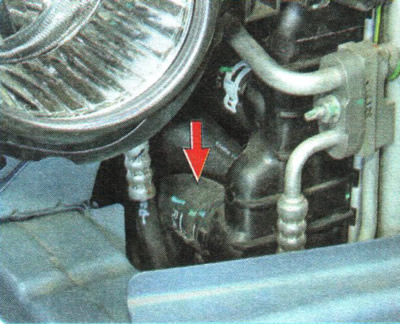

4. Inspect the connections of the cooling system hoses with the heater radiator pipes...

5....and with thermostat module connections.

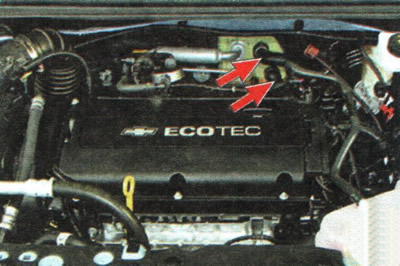

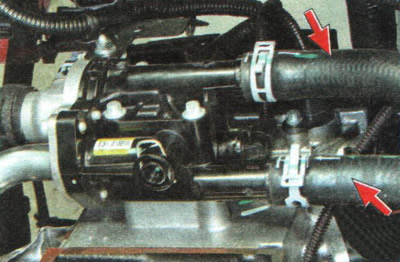

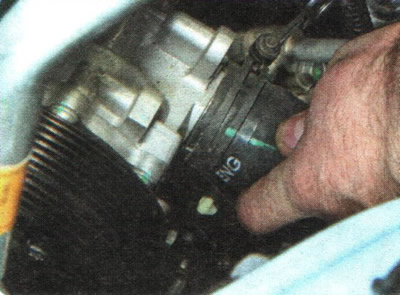

6. Check the tightness of the hose connections to the water pump...

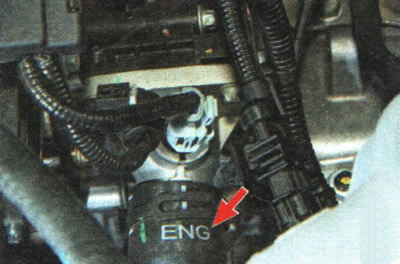

7....with thermostat...

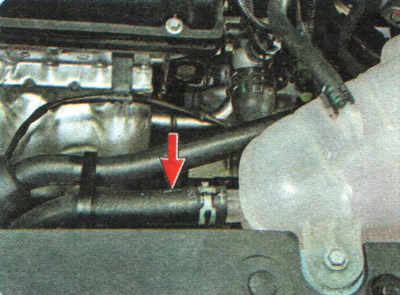

8....expansion tank...

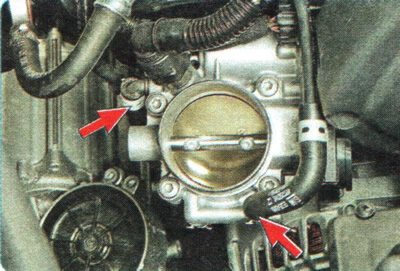

9.... and a throttle assembly.

NOTE: Shown with air hose removed for clarity.

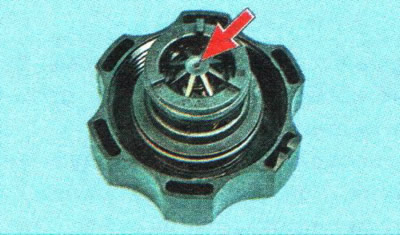

USEFUL ADVICE: There are two valves installed in the plug of the expansion tank: inlet and outlet. The exhaust valve plays a big role in ensuring optimum engine temperature. It maintains an excess pressure of at least 0.12-0.13 MPa in the system (1.2-1.3 kgf/cm2), providing an increase in the temperature of the start of boiling of the coolant and preventing intense vaporization. Unfortunately, when the valve is stuck in the closed position during overheating, a significant overpressure occurs - more than 0.2 MPa (2 kgf/cm2), which can lead to a rupture of the expansion tank or a breakdown of one of the hoses. In turn, the jamming of the valve in the open position leads to premature boiling of the coolant.

Therefore, once a year, rinse the cap of the expansion tank with running water, and check the valve for sticking by pressing with a thin screwdriver. If in doubt, replace the plug.