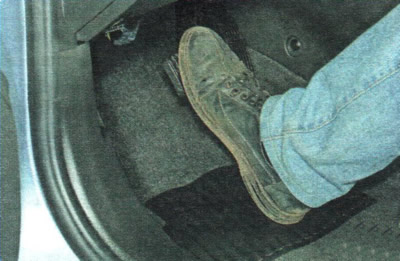

1. The reason for the decrease in braking efficiency may be the unsatisfactory operation of the vacuum booster. For its express check, press the brake pedal several times with the engine off to remove the vacuum in the amplifier, and then, while holding the pedal, start the engine. If the pedal drops a little after starting the engine, the vacuum booster is working. If the pedal remains motionless, check the vacuum booster in the manner described in subsection «Checking the operation of the vacuum brake booster».

2. If braking is accompanied by a beating and pulsation of the brake pedal, you should first check the condition of the front disc brakes. To do this, you need to remove the front wheels one by one, setting the car on reliable supports.

3. Inspect the brake discs. The surface of the disc must be even and smooth on both sides. If the surface of the disc is covered with rust in places, which usually happens after a long parking of the car with wet brakes, try cleaning the working surface with a fine emery cloth. If this procedure does not help, you will have to give the discs for grinding or replace them with new ones.

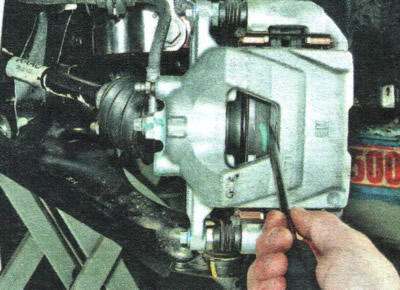

4. Check up mobility of pistons of brake mechanisms. To do this, try to move the pistons out of place with a screwdriver. If the piston cannot be moved, then it is stuck in the brake cylinder.

WARNING: A jammed brake cylinder piston causes the corresponding wheel to brake continuously when the pedal is released and the vehicle to skid when braking.

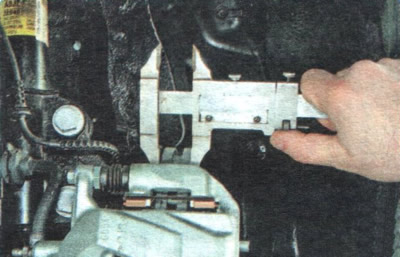

5. Check the thickness of the brake discs and brake pads (see «Checking the degree of wear of brake pads, discs and drums»). If the thickness of the discs or pads is less than the maximum allowable, replace the parts with new ones.

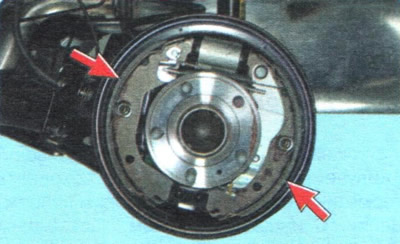

6. If braking is accompanied by jerks of the car and a creak in the region of the rear wheels, and with intensive braking, the rear of the car skids, check the condition of the brake mechanisms of the rear wheels. To do this, one by one, remove the rear wheels, setting the car on reliable supports.

7. Remove the brake drums (see «Removal and installation of a brake drum»). The working surface of the drum must be flat and smooth, without ring marks and clearly visible ovality (ovality can be determined by the unevenly worn working surface of the drum). If the ring risks are very deep or uneven wear of the working surface is clearly visible, the drum will have to be replaced with a new one.

8. Inspect the brake pads. If the pad surface is oily or the pads are loose from the base, replace the brake pads.

9. Measure the thickness of the friction linings of the brake pads and the diameter of the working surface of the brake drum (see «Checking the degree of wear of brake pads, discs and drums»). If the thickness of the pads or the internal diameter of the drum is out of range, replace the parts with new ones.