To start a serviceable engine, you just need to turn on the starter without touching the accelerator pedal. On a vehicle with a manual transmission, you must also depress the clutch pedal. The engine management system will independently set the fuel supply and ignition timing parameters necessary for starting.

The crankshaft does not rotate with the starter

It happens that the starter «does not respond» by turning the ignition key or barely turning the engine crankshaft. Sometimes the crankshaft does not rotate, but when the starter is turned on, multiple clicks are heard.

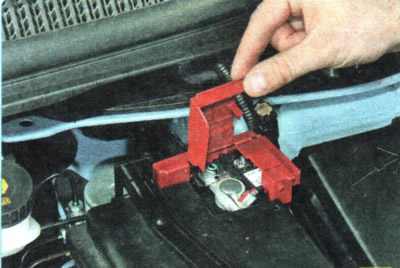

The cause is usually a dead battery or a loose cable lugs on its terminals. If the wire lugs are tight and the starter «does not turn», you can try to start the engine using the battery- «donor» (see «Starting the engine from external current sources»).

GOOD ADVICE: If the battery is completely discharged in a vehicle that has just been stopped, check the battery charging system (see «The battery does not charge»).

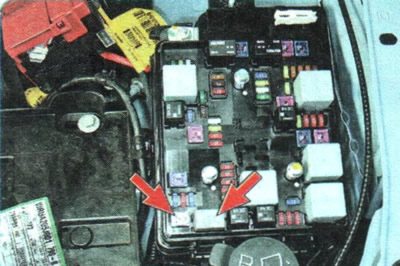

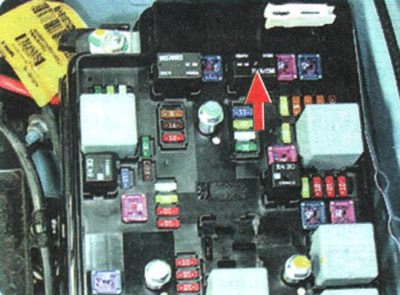

If the starter armature does not start to rotate even with a good battery, check if the fusible insert No. 54 has burned out and whether the starter relay No. 55 is securely fixed in the mounting block of the engine compartment.

In addition, in road conditions, you can check the mount «massive» battery and starter wires to the body. To do this, remove the battery tray (see «Removal and installation of the shelf of fastening of the rechargeable battery»).

To further check the starting system, you will have to call a tow truck, since the car needs to be installed on a lift or inspection ditch.

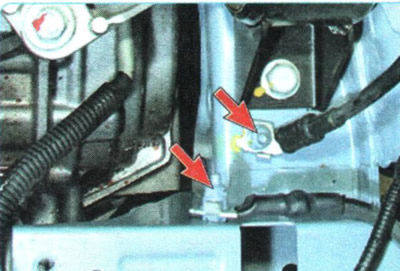

1. Having removed the crankcase protection and the front engine mudguard (see «Removal and installation of mudguards and engine crankcase protection»), check the tightening of the starter contact connections.

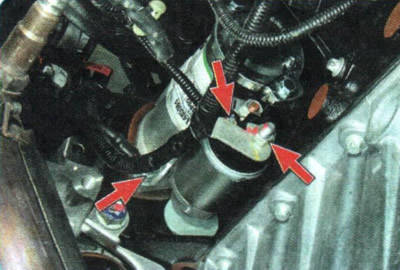

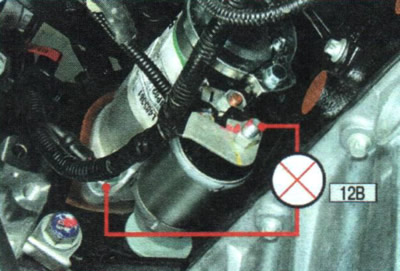

2. Check up presence of pressure on power contact of the traction relay of a starter. To do this, connect one wire of a 12-volt lamp to «weight», and the second - with a contact bolt. If the lamp lights up, the starter power circuit is OK. Otherwise, check and repair the power circuit (see «Diagnostics of malfunctions of onboard electrical equipment»).

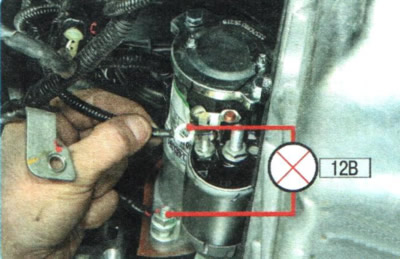

3. If the wire lugs are securely tightened, the power circuit is good, and the starter does not work, disconnect «mass» (disconnect the wire from the terminal «minus» battery) and disconnect the control wire from the traction relay (see «Removal and installation of a starter»). Connect a 12V bulb between the control wire end and «weight». Securely isolate the tip of the power wire disconnected from the traction relay or install it in place to prevent the tip from touching the metal parts of the car, then turn on «mass» (connect the wire to the terminal «minus» battery). Have an assistant turn the ignition key to position «starter». If the lamp lights up, remove and repair the starter (see «Starter repair»). If the lamp does not light, check and repair the starter control circuit, see «Diagnostics of malfunctions of onboard electrical equipment»).

NOTE: Sometimes it happens that when the ignition key is turned, the starter turns on, its armature rotates, but the flywheel remains stationary. Causes may include loose starter to clutch housing, damaged flywheel or drive gear teeth, drive freewheel slip, broken starter drive lever, drive ring, or buffer spring.

The crankshaft rotates, but the engine does not start

If the starter turns the crankshaft confidently, but the engine does not start after three or four attempts, then in this case the power supply system or engine management system is most often faulty (the engine management system also includes the ignition system).

To test the power system on the road, do the following.

1. Open the hood and check for leaks in the engine power system connections. Look under the car for leaks in the fuel tank and fuel lines.

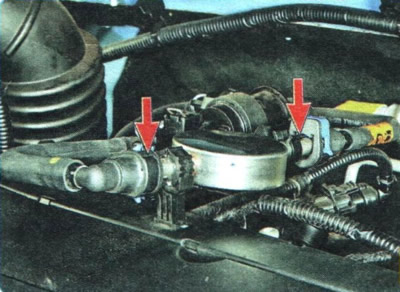

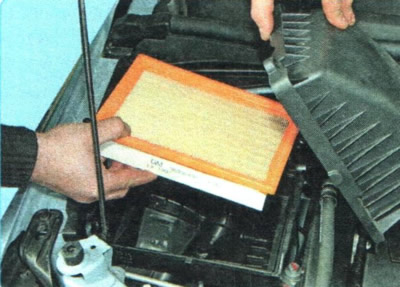

2. Remove the air filter element (see «Replacing the air filter element»), replace the filter cover and try to start the engine. If the engine starts, replace the filter element.

NOTE: Never make even short trips without an air filter element: road dust will immediately damage the engine cylinder-piston group.

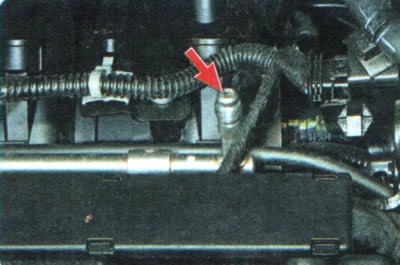

3. If the engine does not start, unscrew the fitting cap under the hood to check the fuel pressure in the fuel rail.

4. To protect against fuel splashes, take a large, highly absorbent rag and place it around the nozzle. Carefully press a screwdriver on the stem of the spool valve. If fuel squirts out of the nozzle, the pressure in the fuel system is sufficient to start the engine. In this case, proceed to check the engine management system (see below).

WARNING: Fuel leaks in the engine compartment are a fire hazard, therefore, before continuing work, carefully wipe off traces of fuel and ventilate the engine compartment.

5. If the check showed the absence of the required fuel pressure in the rail, turn on the ignition and listen: within a few seconds you should hear the sound of the electric fuel pump in the area of the fuel tank (under the back seat).

NOTE: Keep in mind that if there is pressure in the fuel rail, the electric fuel pump will not turn on. This is not a malfunction.

6. If the fuel pump hums with the ignition on, but does not create pressure in the fuel rail, the fuel inlet mesh or filter built into the fuel module, a faulty fuel pump or pressure regulator are to blame. With all these malfunctions, it is necessary to replace the non-separable fuel module. This can only be done when the vehicle is placed on a lift or pit (see «Removal and installation of the fuel module»).

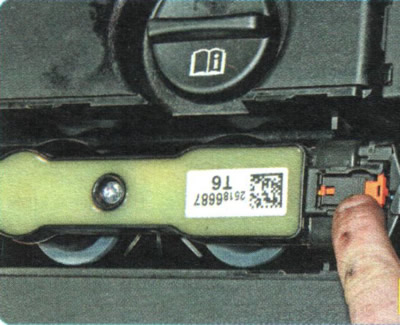

7. If the sound of the fuel pump is not heard, it is necessary to check and restore the power supply circuit of the fuel pump (see «Diagnostics of malfunctions of onboard electrical equipment»), and if it is OK, you should replace the fuel module with a burnt or jammed pump (see «Removal and installation of the fuel module»). To do this, you will need to remove the fuel tank (see «Replacing the fuel tank and its filler pipe»). That is why such a check is impossible in road conditions. On the road, you can only check if fuse No. 35 has blown and whether the fuel pump relay No. 34 is securely fixed in the engine compartment mounting block.

The engine management system should be checked using special diagnostic tools (see «Engine malfunctions»).

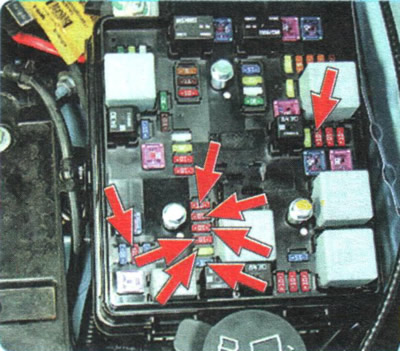

If there is no diagnostic device, on the road, check the integrity of fuses No. 36,42,45,46, 47, 48, 49, 50 in the engine compartment mounting block...

... and the reliability of mounting relay No. 3 of the fuel injection system and the ignition system in the same mounting block.

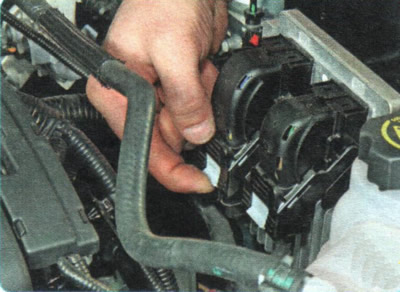

In addition, in the engine compartment, check the reliability of connecting all the blocks of the engine wiring harness accessible for inspection, paying special attention to the blocks of the electronic engine control unit...

... ignition coil unit (see «Removal and installation of the block of coils of ignition»)...

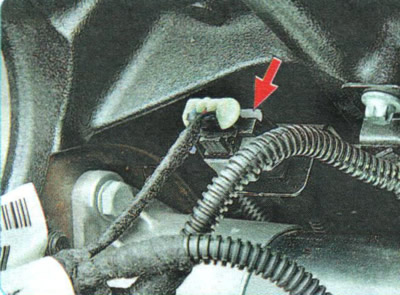

... crankshaft position sensor (the pad is located at the rear of the engine block, behind the starter) and other sensors of the engine management system (see «Codes of malfunctions of a control system of the engine»).

If the test does not reveal any irregularities, use the diagnostic tool (see «Engine malfunctions») or contact a car service.

USEFUL ADVICE: If the engine is badly worn out, in the cold season it starts with difficulty even with serviceable power supply and engine control systems.

If during an unsuccessful start attempt there are «flooded» spark plugs, use the cylinder purge mode. To do this, press the accelerator pedal to the stop and, holding it pressed, turn on the starter. In this mode, there is no fuel supply and excess gasoline is removed from the cylinders by a stream of fresh air, while the spark plugs are dried. After purging, try starting again in the normal way.