Maintaining the correct air pressure in your tires provides the best combination of vehicle handling, tire durability and your comfort. Low tire pressure leads to rapid and uneven wear of the tread, impairs vehicle handling, increases fuel consumption and, in addition, makes tires more likely to fail due to overheating. Tires with excessively high air pressure impair the smoothness of the vehicle and are more susceptible to damage from hitting road ledges, potholes, etc. and, in addition, excessively high air pressure in the tires causes uneven tread wear. It is recommended to visually check the air pressure in the tires daily. If you have determined by eye that the tire pressure has decreased, check the air pressure with a tire pressure gauge. Check the air pressure in all tires with a tire pressure gauge at least once a month. Even in fully serviceable tires, air pressure can drop by 10-20 kPa in a month (0.1-0.2 kgf/cm2). Remember to check the air pressure in the spare tire at the same time as checking the other wheels. Check air pressure only on cold tyres. The tires can be considered cold if at least three hours have passed since the car was stopped, or if after a long period of parking the car you have driven a distance of no more than 1.5 km. Inflate the tire, if necessary, or bleed some of the air out of the tire to bring the pressure up to the pressure indicated on the decal affixed to the door pillar on the driver's side. After driving a car for a distance of several kilometers, the tires have time to heat up, and the air pressure in them increases by 30-40 kPa (0.3-0.4 kgf/cm2) compared to the cold state. This is not a malfunction. Do not reduce the air pressure in warm tires to bring it to the nominal value that is set for cold tires. Otherwise, the tires will run at reduced air pressure.

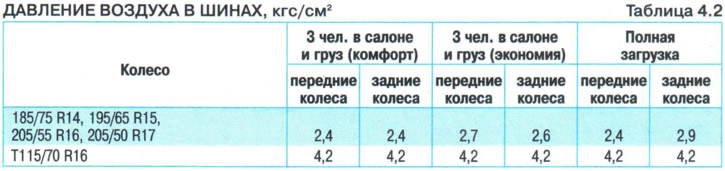

RECOMMENDATIONS: Check tire pressure regularly (tab. 4.2). Maintaining nominal air pressure in tires provides the best combination of tire durability, handling and vehicle comfort.

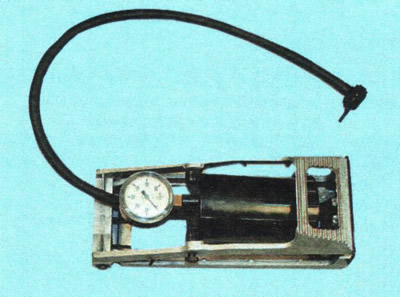

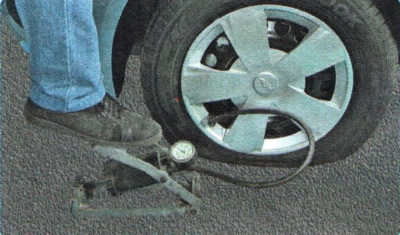

We recommend using a foot or electric pump with a built-in pressure gauge.

Every time you check the air pressure in the tires, carefully inspect them for mechanical damage to the tread and sidewalls, small stones, nails stuck in the tread, signs of severe tread wear. Pay special attention to the following tire defects:

- local swelling or bulging of the carcass in the tread area or on the sidewalls. A tire with a similar defect must be replaced;

- cuts, cracks or delamination of the sidewall frame. Replace the tire if the carcass cord is exposed.

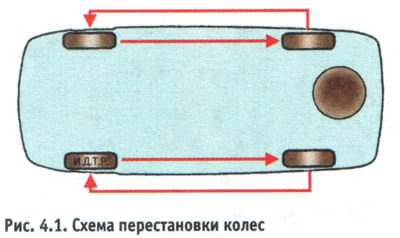

In order for the tires to wear out evenly, rearrange the wheels every 10,000 km in accordance with the diagram in Fig. 4.1.

In addition, every 20,000 km, balance the wheels and check the alignment of the front wheels. To do this, contact a specialized workshop.

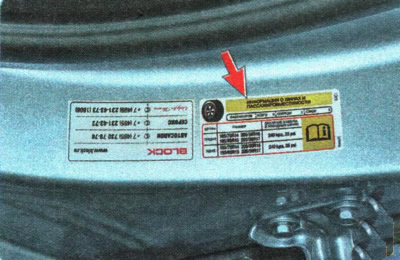

NOTE: There is a sticker on the B-pillar in the driver's door opening that indicates the air pressure in the tires for various vehicle loading conditions.

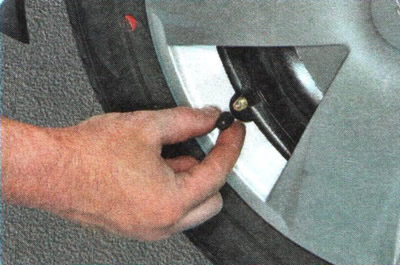

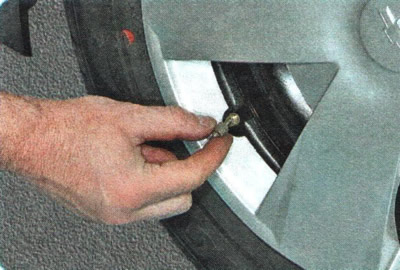

1. Unscrew the cap from the valve.

2. Check tire pressure. To do this, reset the pressure gauge to zero by pressing the special button on the pressure gauge housing...

3.... connect a pressure gauge to the valve and press the valve spool with the tip of the pressure gauge.

4. If the pressure is less than required, connect the tip of the pump hose to the valve and pump air, controlling the pressure on the pressure gauge on the pump.

5. If the pressure is more than required, press the special protrusion of the pressure gauge on the tip of the spool and release the air from the tire. Measure the pressure with a manometer. By repeating these operations, bring the pressure to normal.

NOTE: Remember to check the air pressure in the spare tire at the same time as checking the pressure in the other tires.

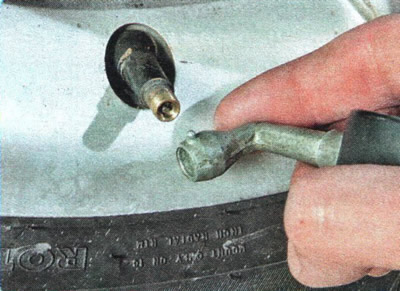

6. If you notice that the air pressure in the tires is constantly dropping, try tightening the spool with a cap with a key.

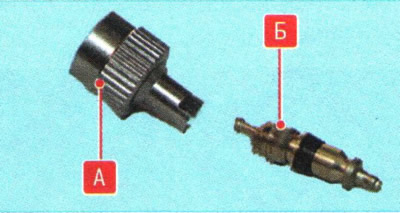

NOTE: This is how the protective cap A with the key for tightening the spool and the spool B of the wheel valve look like.

WARNING: To avoid contamination of the valve stems, do not operate the vehicle without the protective caps. If the caps have been lost, be sure to install new ones.

7. Apply liquid to the valve so that it fills its cavity.

8. If bubbles continue to form and the spool cannot be tightened, replace it. If the replacement does not help, replace the valve.

9. Measure the remaining tread depth with a caliper. If the tread depth is 1.6 mm or less, replace the tire.

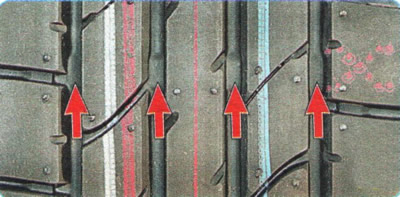

10. If there is no caliper at hand, then the tread depth can be checked visually by tire wear indicators in the form of continuous transverse stripes that appear on the tread at its maximum wear.

WARNING: The tires that your vehicle is equipped with have wear limit indicators molded into the tread. With significant tread wear, smooth transverse strips about 10 mm wide appear on its surface, located with a certain step along the circumference of the tire. Their appearance indicates a decrease in the depth of the tread pattern to 1.6 mm. Worn tires do not provide sufficient grip when driving on wet road surfaces. Therefore, if three wear indicators are visible on the tread (or more than three), the tire must be replaced.

The indicator locations are marked on the sidewall of the tire with a triangular symbol...

...or letters «TWI» (tread wear index).

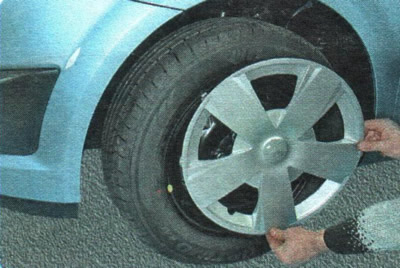

11. Remove the decorative cap...

NOTE: A vehicle equipped with alloy wheels does not have a decorative cap.

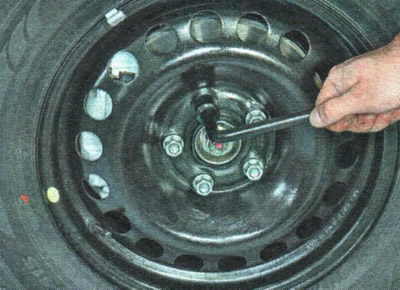

12.... check the tightness of the wheel nuts and, if necessary, tighten them to 90 Nm.