Before disassembling the starter, make sure it is in good condition by following these simple checks.

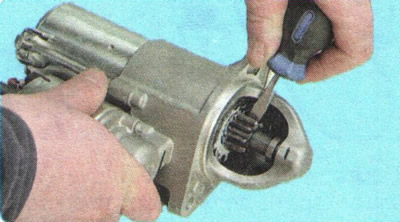

1. Using a screwdriver, check the ease of movement of the drive coupling along the shaft.

2. Rotate the drive gear. It should rotate easily relative to the coupling hub in the direction of rotation of the armature and should not rotate in the opposite direction.

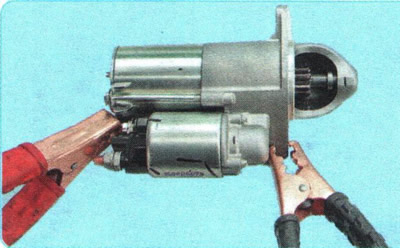

3. Wire for «smoking» terminal «minus» the battery removed from the car with the starter housing. Connect the second wire at one end to the terminal «plus» battery, and the second - to the output of the control wire of the traction relay. If the traction relay is working properly, a click will be heard and the drive clutch will extend. Otherwise, the traction relay must be replaced.

4. Disconnect the wire from the control output of the traction relay and connect it to the bottom contact bolt of the traction relay. The starter rotor should begin to rotate at a frequency of more than 6000 min-1. Otherwise, repair the starter.

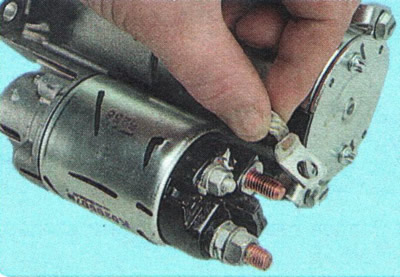

1. Unscrew the nut securing the tire to the contact bolt of the traction relay...

2.... and disconnect the tire from the bolt.

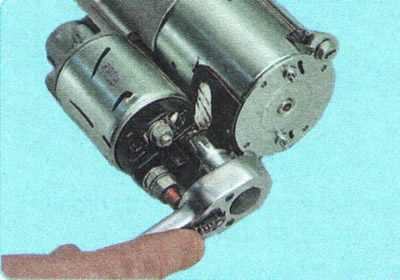

3. Turn out three bolts of fastening of the traction relay to a cover...

4.... and remove the traction relay.

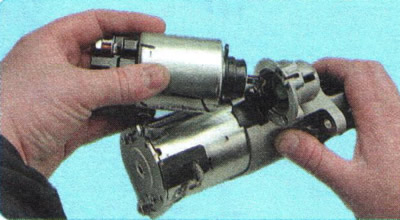

5. Turn out two coupling bolts...

6.... and separate the stator and cover.

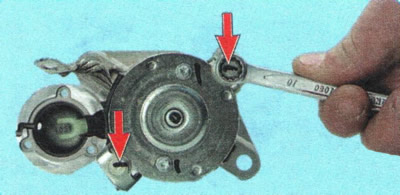

7. Turn out two bolts of fastening of a cover from a collector...

8.... and remove the cover.

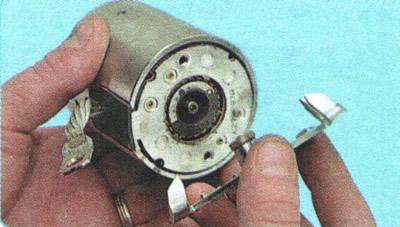

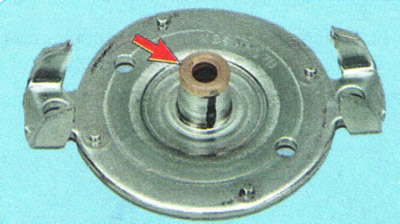

9. Examine the cover. If the bushing in the cover is worn out or there are scuffs, shells and other defects on it, it is necessary to replace the cover assembly with the bushing.

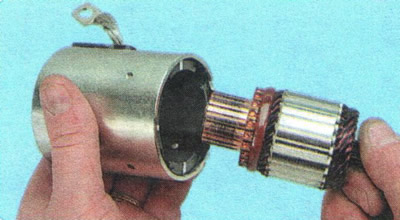

10. Remove the rotor from the stator...

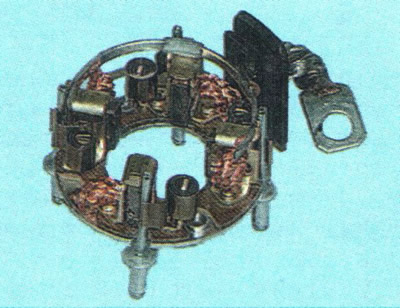

11.... and a brush assembly.

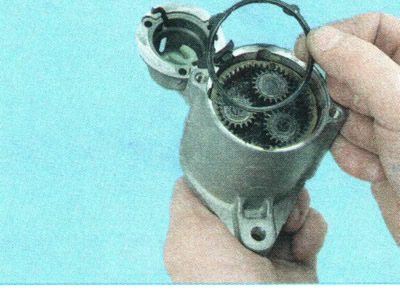

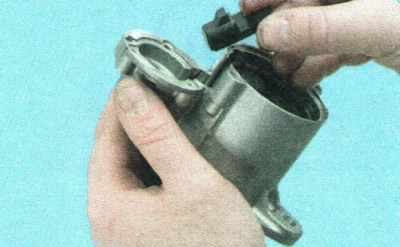

12. Remove the oil deflector cover of the planetary gear...

13.... and an o-ring.

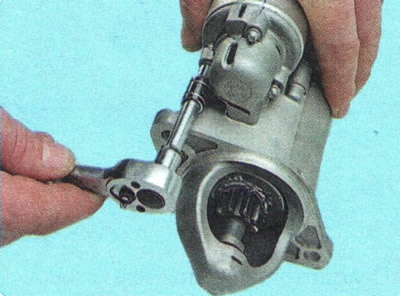

14. Remove the starter drive lever support from the drive side cover.

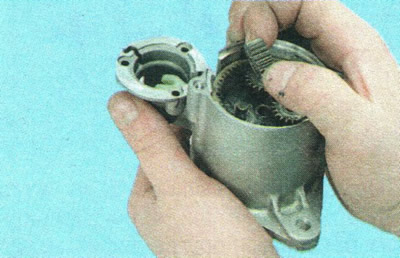

15. Remove three satellites from carrier axles.

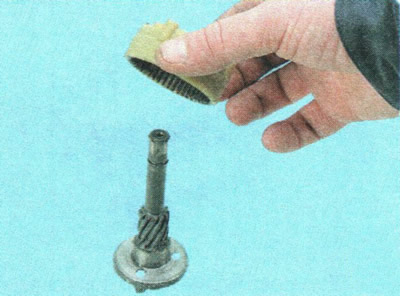

16. Remove the drive shaft from the cover...

17.... and remove the drive lever.

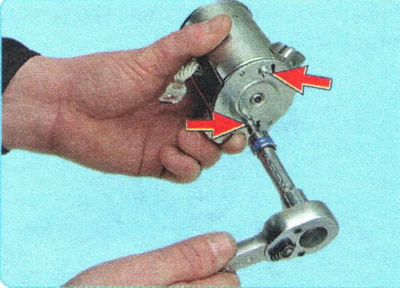

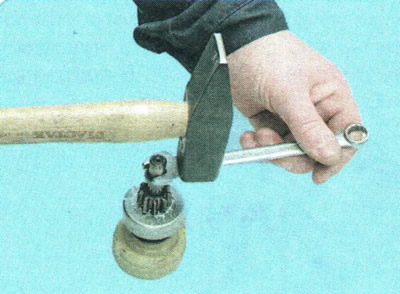

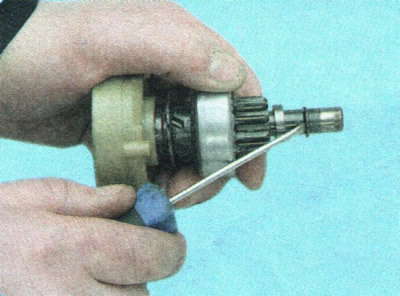

18. Slide the restrictive ring along the drive shaft, as shown in the photo.

19. Prying with a screwdriver, remove the retaining ring.

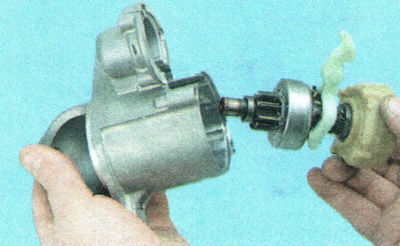

20. Remove the restrictive ring...

21.... and a drive clutch.

22. Remove the planetary gear ring gear.

23. Inspect the brush assembly. Check the height of the brushes in the brush holder. If their height is 7 mm or less, replace the brush assembly with a new one. Use an ohmmeter to check the insulated holders for a short to the housing. The resistance should tend to infinity.

24. Inspect the rotor. There must be no damage on the gear and trunnions of the rotor shaft (nicks, burrs). The rotor manifold must not show signs of burning. Eliminate minor burns with a rag soaked in gasoline and fine-grained emery cloth. Check the rotor winding for a short circuit with an ohmmeter. The resistance should tend to infinity.

25. Check whether the armature of the starter traction relay moves easily, whether the contact bolts of the contact plate close (using an ohmmeter).

26. Check drive clutch. Gear teeth should not be significantly worn. The gear must be able to rotate easily relative to the coupling hub in the direction of rotation of the rotor and must not rotate in the opposite direction. If the gear teeth are worn or damaged, or the gear turns in both directions, replace the clutch.

27. There should be no cracks or signs of significant wear on the fork groove on the starter drive lever.

28. Assemble the starter in the reverse order of disassembly, taking into account the following:

- lubricate the rotor shaft gear with General Electric CG321 silicone grease or equivalent;

WARNING: The drive clutch does not need to be lubricated during operation. However, it must be cleaned of dirt. Do not use cleaners to clean the drive that can wash out the lubricant embedded in its coupling.

- lubricate the bearings with engine oil (bushings), in which the starter rotor rotates;

- use pliers to install the restrictive ring;

- before installing the brush assembly on the rotor, separate the brushes and fix them in any way possible (e.g. rivets or small nails). After installing the brush assembly on the rotor, release the brushes by removing the installed clamps;

- Apply a thin layer of silicone sealant to the surface of the relay that contacts the starter cover on the drive side before installing the pull relay.