Complete disassembly of the generator in a garage is not recommended, so if necessary, it is better to contact a workshop that specializes in repairing generators. This subsection shows only the replacement of the voltage regulator assembly with the brush assembly and bearings.

1. Remove the alternator from the vehicle (see «Removal and installation of the generator»).

2. Holding the generator shaft with a hex key, unscrew the pulley fastening nut...

3.... and remove the pulley from the shaft.

4. Turn away two nuts of power conclusions of the generator.

NOTE: The protective cover is attached to the power terminal nuts at the same time.

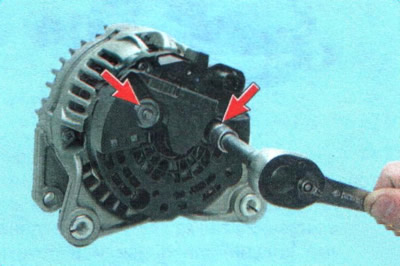

5. Turn out the screw of fastening of a protective casing...

6.... and remove the casing.

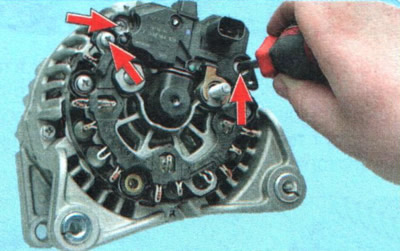

7. Remove the three screws securing the voltage regulator with the brush assembly...

8.... and remove the voltage regulator.

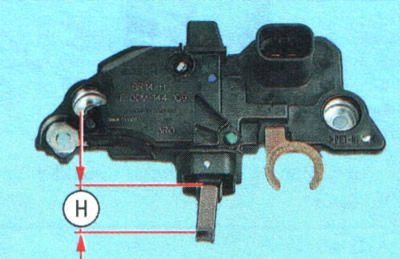

NOTES: This is what the voltage regulator with brush assembly looks like removed from the alternator. Check the protrusion of the brushes in a free state. If the H dimension is less than 3 mm, replace the brushes or brush assembly. Check the ease of movement of the brushes in the brush holder. If they are wedged, the brush assembly also needs to be replaced.

9. Check with an ohmmeter (tester) resistance of the rotor winding by connecting it to slip rings. If the ohmmeter shows infinity, then there is a break in the windings and the rotor needs to be replaced.

10. Tag (e.g. marker) the mutual arrangement of the covers of the generator, in order to ensure the alignment of the holes in the paws for attaching the generator during reassembly.

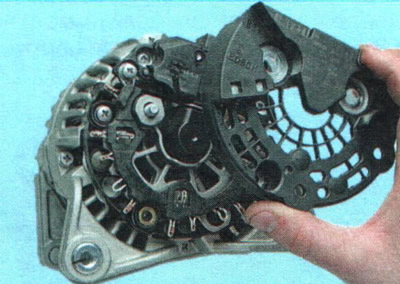

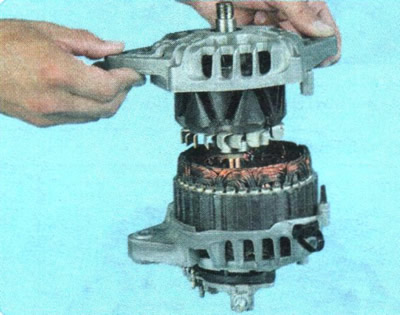

11. Turn out four coupling bolts. Pry with a screwdriver between the covers...

12.... and remove the front cover along with the rotor.

NOTE: The rectifier unit, the stator winding and the back cover are a single unit and are not subject to further disassembly in garage conditions, since the stator winding terminals are connected to the terminals of the rectifier unit by contact welding.

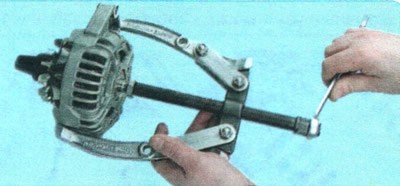

13. Press the rotor out of the front cover.

USEFUL ADVICE: In order not to damage the threaded shank of the rotor shaft with the puller screw, screw the pulley fastening nut flush with the end of the shaft onto it.

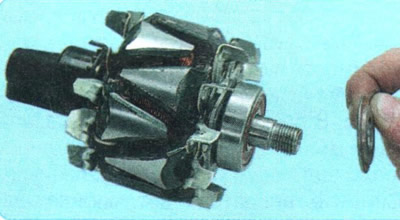

14. Remove the spacer washer from the front end of the rotor shaft...

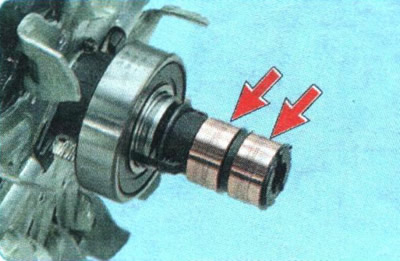

15.... and a centering sleeve from the rear bearing of the rotor shaft.

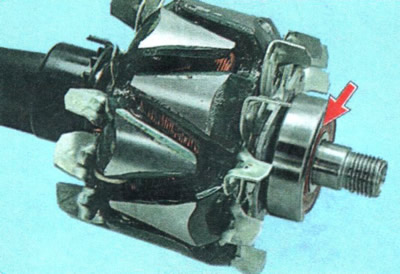

16. Inspect the plastic centering sleeve of the rotor shaft rear bearing. The centering sleeve must be firmly seated in the hole in the cover. If the bearing is correctly seated in the sleeve, there should be no evidence of slippage of the bearing outer ring.

17. Inspect the rotor shaft front bearing. If during rotation of the bearing there is play between the rings, rolling or jamming of the rolling elements, damaged protective rings or grease leaks, replace the bearing. To replace the bearing, press it off the rotor shaft with a universal puller. Press the new bearing onto the shaft, applying force only to its inner ring.

WARNING: Pressing a bearing against its outer race will damage the bearing.

18. Examine contact rings. If they have scuffs, scratches, scratches, wear marks from brushes and other damage, the rings must be ground. If damage to the rings cannot be removed with sandpaper, you can grind the rings on a lathe, removing the minimum layer of metal, and then grind.

19. Check the resistance of the rotor winding with a tester by connecting it to slip rings. The resistance should be approximately 3-5 ohms. If the tester shows infinity, then there is a break in the rotor winding - the rotor must be replaced.

20. Check the absence of a short circuit in the rotor winding to the housing by connecting the tester leads to any slip ring and the rotor housing. The tester should show infinity.

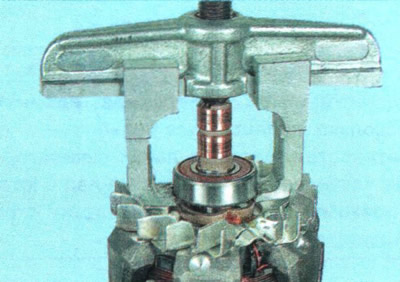

21. Check up ease of rotation of the bearing from slip rings. If during rotation of the bearing, play is felt between the rings, roll or jamming of the rolling elements, protective rings are damaged or grease leaks are detected, the bearing should be replaced. For this...

22.... press the bearing off the rotor shaft.

23. Press the new bearing onto the rotor shaft until it stops against the shoulder of the shaft, applying force only to the inner race of the bearing through a mandrel of suitable diameter.

24. Assemble the generator in the reverse order of disassembly, orienting the generator covers and the stator according to the previously made marks.