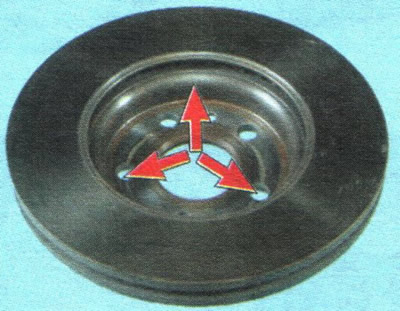

If there are scuffs, deep scratches and other defects on the working surface of the disc that increase pad wear and reduce braking efficiency, as well as in case of increased lateral runout of the disc, causing vibration during braking, replace the disc. In specialized workshops, such a disc can be machined and polished on both sides to the same depth, but after processing, the thickness of the disc must not be less than the minimum allowable (24 mm). The minimum allowable thickness of the brake disc of the brake mechanism of the front wheel when worn is 23 mm. If the thickness of one of the discs is less than the specified value, replace both discs. When replacing brake discs, be sure to replace the brake pads with a new set.

1. Remove the wheel from the side of the disc being replaced.

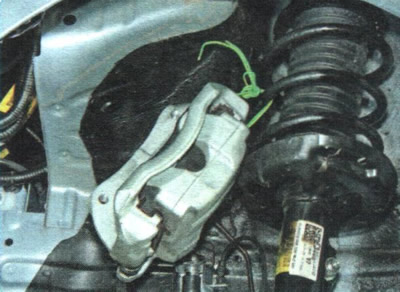

2. Remove the caliper (see «Front wheel brake caliper replacement»), without disconnecting the brake hose, and secure with wire to the front suspension spring. Do not twist or strain the hose while doing this.

NOTE: To be able to wire the caliper to the front suspension spring, remove the brake hose holder from the bracket slot on the shock strut before removing the caliper.

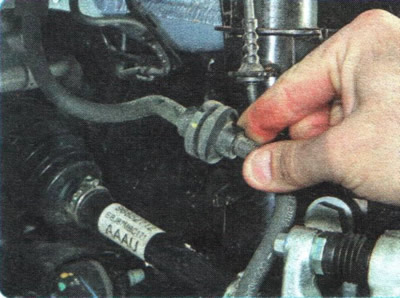

3. Turn out a bolt of fastening of a disk to a nave...

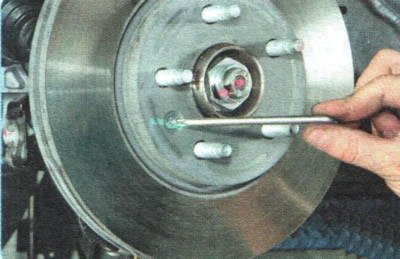

4....and remove the disc.

5. Similarly remove a brake disk of the brake mechanism of other forward wheel.

6. Install the parts in the reverse order of removal.

NOTE: Before installing the disc, carefully clean the hub and disc mating surfaces of rust and scale, as even the smallest particle sandwiched between the mating surfaces will cause the disc to wobble and vibrate when braking.

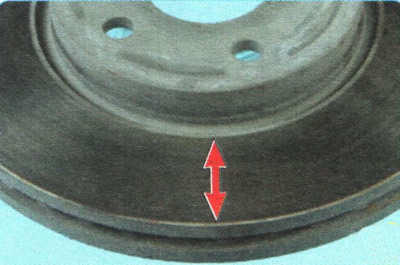

USEFUL ADVICE: If you install the old disc, remove with a file the shoulders on the working surfaces of the disc, formed on both sides as a result of disc wear, otherwise, in addition to increased wear of the brake pad linings, braking will be accompanied by jerks.