If one of the circuits of the working brake system fails, the second circuit is used, which ensures that the car stops with sufficient efficiency.

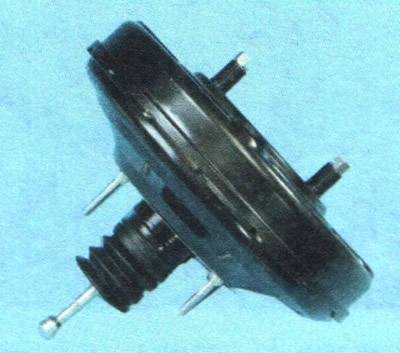

A vacuum booster is included in the hydraulic drive. The vehicle has an anti-lock braking system (ABS), electronic brake force distribution (EBD) and emergency brake assist (Brake Assist).

Parking brake system - with a cable drive to the brake mechanisms of the rear wheels.

Front wheel brake disc, with automatic adjustment of the gap between the pads 5 (pic. 9.1) and disk 7, with a floating bracket. Movable (floating) the bracket is a caliper 6 with a single-piston working cylinder. The shoe guide 3 is bolted to the steering knuckle. The movable bracket is attached with guide pins 4 screwed into the threaded holes of the guide shoe. The guide pins are grease lubricated and protected by rubber bellows. A piston with a sealing ring is installed in the cavity of the working cylinder. Due to the elasticity of this ring, the optimal clearance between the pads and the ventilated disc is maintained. When braking, the piston, under fluid pressure, presses the inner pad against the disc, under the influence of the reaction force, the caliper moves on the fingers and the outer pad is also pressed against the disc, while the pressing forces of the pads are the same. When releasing the piston, due to the elasticity of the sealing ring, it is retracted from the pad, as a result, a small gap forms between the pads and the disc.

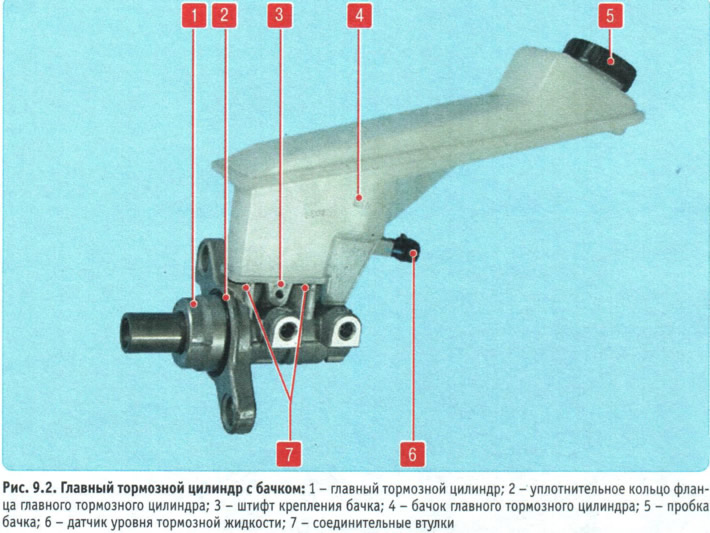

Master brake cylinder type «tandem» hydraulic brake actuator is installed in the engine compartment directly on the vacuum brake booster.

It consists of two separate chambers connected to independent hydraulic circuits. The first chamber is connected to the right front and left rear brake mechanisms, the second - to the left front and right rear.

To the master cylinder through rubber connecting bushings 7 (pic. 9.2) tank 4 is installed, the internal cavity of which is divided by partitions into three compartments. Each compartment feeds one of the brake master cylinder chambers and the clutch release master cylinder (only on vehicles with manual transmission).

When you press the brake pedal, the pistons of the main brake cylinder begin to move, the working edges of the cuffs cover the compensation holes, the chambers and the reservoir are separated and the brake fluid is forced out.

Brake fluid level sensor 6 is installed in the lower half of the tank body. If the fluid level falls below the permissible level, the warning lamp for a malfunctioning brake system lights up in the instrument cluster. The connection between the master brake cylinder and the vacuum brake booster is sealed with a rubber ring 2.

vacuum booster, installed between the pedal mechanism and the main brake cylinder, when braking due to the vacuum created by the vacuum pump, as well as the vacuum in the engine intake pipe through the rod and piston of the first chamber of the main cylinder, it creates an additional force proportional to the force from the pedal.

Vacuum pump with an electric drive is installed on the left side member of the engine compartment and creates a constant vacuum necessary for the operation of the vacuum brake booster when the vacuum drops in the engine intake pipe during its operation in power modes, as well as when the engine is not running.

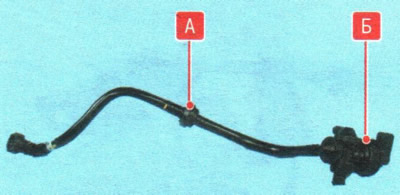

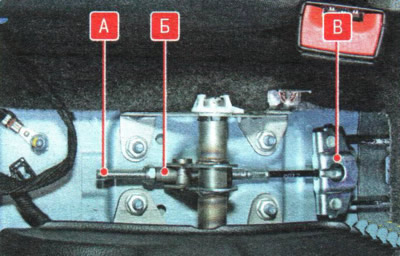

The combination hose connecting the vacuum booster to the vacuum pump and the engine intake pipe has a non-return valve A. It holds the vacuum in the booster when it drops after the ignition is turned off. An electrically controlled two-way valve B is installed in the same hose, with the help of which the electronic engine control unit, depending on the engine operating modes, switches the vacuum supply to the vacuum brake booster or from the engine intake pipe or from the vacuum pump.

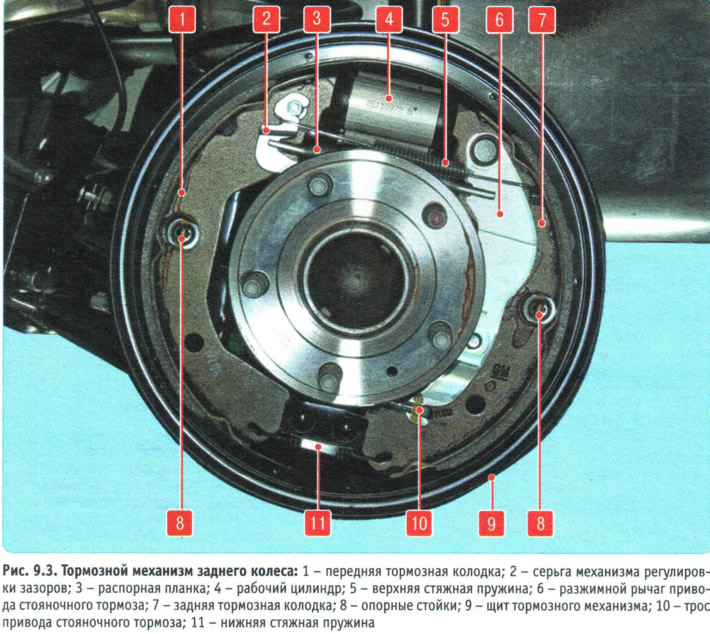

Rear wheel brake drum, with automatic adjustment of the gap between the shoes and the drum. Brake pads 1 and 7 (pic. 9.3) are driven by one hydraulic working cylinder 4 with two pistons. The optimal clearance between the drum and the shoes is maintained by a mechanical regulator mounted on the spacer bar 3. As the lining of the shoes wears out, the earring 2 turns the regulator nut and its threaded tip lengthens, compensating for the increasing gap between the spacer bar and the edge of the front shoe.

Parking brake, mechanically actuated, consists of a lever mounted on the base of the body between the front seats...

...and front cable A (floor tunnel lining removed for clarity) with adjustment device B and equalizer C, to which two rear cables are attached. The ends of the rear cables are connected to the expansion levers of the brake mechanisms of the rear wheels. Expanding levers act on the rear brake pads 7 (see fig. 9.3) after the stop of the front pads 1 into the brake drum through the spacer bar 3.

The cable 10 of the parking brake drive, being pulled, turns the expansion lever 6 and presses the front shoe against the brake drum through the spacer bar 3. Having received a hard stop on the spacer bar, the expanding lever presses the rear shoe 7 to the brake drum. After lowering the parking brake lever, the shoes move away from the drum under the action of coupling springs 5 and 11.

The parking brake does not require special care.

Anti-Lock Braking System (ABS) consists of wheel speed sensors, brake light switch, hydroelectronic control unit and signal lamp. In addition, the anti-lock braking system is equipped with a self-diagnosis system that detects malfunctions of its components, and provides functions to maintain operation in case of system failures.

ABS is used to regulate the pressure in the brake mechanisms of all wheels when braking in difficult road conditions, which prevents the wheels from locking.

The modes of operation of the anti-lock braking system are described in detail in Sect. «Anti-Lock Braking System (ABS)».

Diagnostics and repair of the anti-lock braking system requires special equipment and accessories. Therefore, in case of failure, contact a specialized service station.

The hydraulic brake system is integrated into a single unit with metal tubes and hoses. The system is filled with DOT-4 brake fluid.

The procedure for replacing the brake fluid is described in subsection «Replacement of a brake liquid in a hydraulic drive of brakes», With. 195.

Checking the brake system is discussed below.

USEFUL ADVICE: Some drivers, in an effort to wear out the parking brake cables less, try to use it less often.

Such «saving» leads to the opposite result: the cable, rarely moving in the shell, gradually loses mobility, it jams, as a result, the cable breaks. Therefore, use the parking brake whenever necessary. The working stroke of the brake pedal with the engine running should be approximately 60-65 mm. A too small stroke indicates an incorrect initial setting of the brake pedal, a violation of the adjustment of the vacuum brake booster or seizure of the working cylinder, causes increased fuel consumption and accelerated wear of the brake pads. Too large a stroke is a sign of excessive clearances in the pedal mechanism or a violation of the tightness of the hydraulic drive of the brake system. If the stroke decreases when the pedal is pressed repeatedly, i.e. she becomes «tougher», air in the system. If the full pedal travel starts to increase, the system is leaking.

If the brake pedal always starts to vibrate when braking, most likely the brake discs are warped. Unfortunately, in such a situation, they only need to be changed, and both at once. Periodically appearing and disappearing pedal vibration during sudden braking of a car equipped with an anti-lock brake system accompanies the operation of this system and is not a sign of a malfunction.

If the car starts to pull to the side when braking, check the working cylinders: they may need to be replaced.

If there is a knock in the front suspension that disappears when braking, check the tightness of the caliper mounting bolts.

After replacing the brake pads, before driving, be sure to press the brake pedal several times - the pistons in the working cylinders should fall into place.