All parts must be cleaned before assembly.

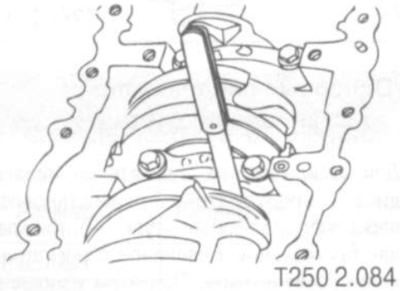

1. Use a plastic gauge to determine the clearances in all crankshaft bearings. See «Selection of connecting rod bearing shells using a plastic gauge» And «Selection of main bearing shells using a plastic gauge».

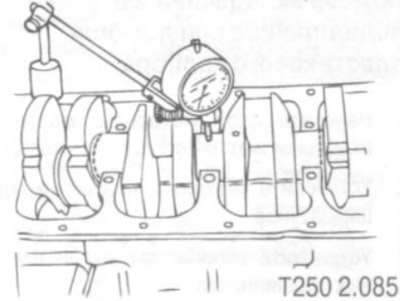

2. Check the radial runout of the crankshaft rear seal journal with the bearings installed.

3. Check up an axial run-up of a cranked shaft.

4. Check up runout of a surface of a neck of the average radical bearing of a cranked shaft.

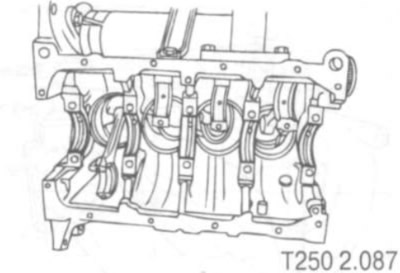

5. Apply a thin coat of engine oil to the crankshaft bearing shells.

6 Install the crankshaft.

7. Apply sealing compound to the rear main bearing cap.

8. Install crankshaft bearing caps #1-4.

9. Install the No. 5 main bearing cap. At the same time, make sure that the sealant evenly seals the cover-to-cylinder block connectors.

Caution: Do not reuse old crankshaft main bearing screws.

10. Tighten the crankshaft main bearing cap screws:

- tighten the screws to 50 Nm;

- tighten to an angle of 45°+ 15°.

11. Install the connecting rod bearing shells into the connecting rods and into the connecting rod bearing caps.

12. Install the connecting rod bearing caps.

Caution: Do not reuse old connecting rod bearing cap screws.

13. Tighten the connecting rod bearing cap screws to 25 Nm.

14. Tighten the connecting rod bearing cap screws 30°+ 15°.

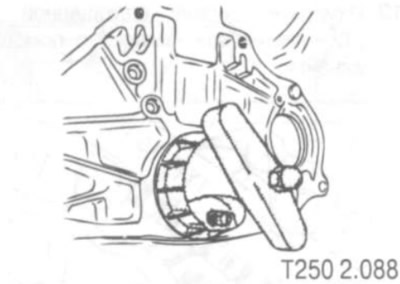

15. Install the oil pump.

16. Tighten the oil pump screws to 10 Nm

17. Install the oil receiver.

18. Tighten the oil receiver screws to 10 Nm.

19. Install the oil pan gasket.

20. Install the oil pan no later than 5 minutes after applying the gasket sealant.

21. Tighten the oil pan screws to 10 Nm.

22. Install the crankshaft sprocket.

23. Install the rear of the timing case.

24. Tighten the screws on the rear of the timing case to 10 Nm.

25. Install the automatic camshaft timing belt tensioner.

26. Tighten the automatic timing belt tensioner screw to 20 Nm.

27. Tighten the camshaft pulley screw to 45 Nm.

28. Install the timing belt.

29. Adjust the tension of the camshaft timing belt.

30. Install the valve cover with gasket.

31. Tighten the camshaft cover screws to 10 Nm.

32. Install the lower part of the timing case.

33. Tighten the screws on the bottom of the timing case to 10 Nm.

34. Install the power steering pump.

35. Tighten the power steering pump screws to 25 Nm.

36. Install the top of the timing case.

37. Tighten the screws of the upper part of the timing case to 10 Nm.

38. Establish a back epiploon of a cranked shaft by means of a mandrel.

39. Install the flywheel.

40. Tighten the flywheel mounting screws to 35 Nm.

41. Tighten the flywheel mounting screws at an angle of 30°+ 15° (see fig. T250 2.069).

42. Install the engine in the car.