2. Check the condition of the connecting rod bearings (only to determine the operating conditions of the engine before repair, since in any case new crankshaft bearing shells should be installed).

3. Check the connecting rod bearing seat for wear.

4. Check the connecting rod bore for nicks or wear.

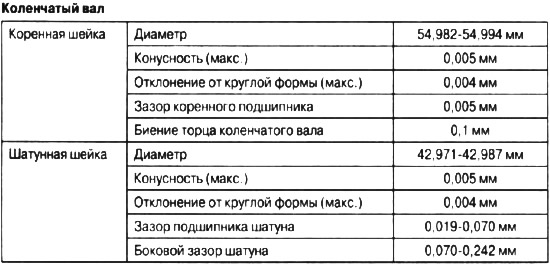

5. Check the crankshaft journals for wear.

6. Check pistons for scoring, chipping and wear.

7. Measure the diameter of the pistons with a micrometer.

8. Check the correct installation of the piston relative to the connecting rod (see labels).

9. Check the cylinder block for flatness of the surface in contact with the head gasket using a ruler and feeler gauge.

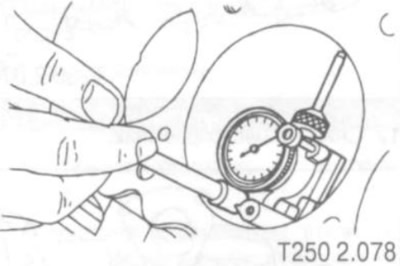

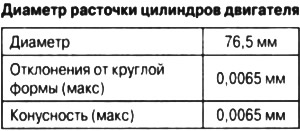

10. Measure the bore diameter of the cylinder at various locations using a bore gauge (at the top, middle and bottom of the cylinder, along two mutually perpendicular diameters).

11. Check the condition of the cylinder walls for protrusions, burnouts of the walls, increased local wear, scoring.

12. Check the condition of the cylinder walls for the presence of varnish and carbon deposits, if necessary, lightly honing to clean.