Front brake check

Check brake pad thickness - minimum brake pad thickness (with metal plate): 7 mm.

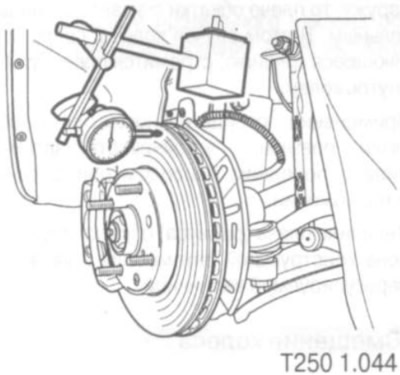

Checking the brake disc

The thickness of the brake disc is measured with a micrometer at four points along the circumference of the disc at an equal distance from the wheel axle. Of significant importance is the difference in measurements of the thickness of the disc, carried out in different places. The maximum allowable measurement difference is 0.10 mm. If the difference is greater, the brake pedal may vibrate when braking.

The runout of the brake disc in the axial direction must not exceed 0.10 mm. The measurement of the runout is made using a dial indicator of displacements.

Roughness of the disc surface is assessed by visual inspection with the use of a pointer indicator. During operation, the presence of concentric recesses on the surface of the disk is allowed. The depth of such recesses should not exceed 0.40 mm.

Pad replacement

1. Remove the front wheel by first lifting and securing the front of the vehicle with a suitable, secure stop.

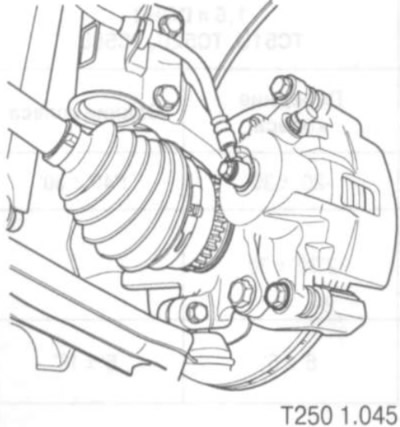

2. Lever (screwdrivers) spread the pads. In this case, the piston of the cylinder is pressed inward. This is necessary so that the pads do not catch on the flange formed on the edge of the disc during its wear.

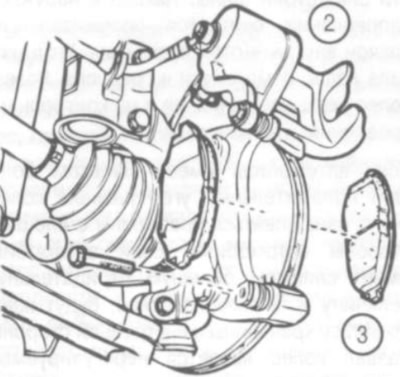

3. Unscrew the lower screw securing the caliper movable bracket and move the bracket up.

4. Remove the brake pads.

1. Screw.

2. Floating caliper bracket.

3. Brake pads.

Installation is in the reverse order. Floating bracket tightening torque: 27 Nm.

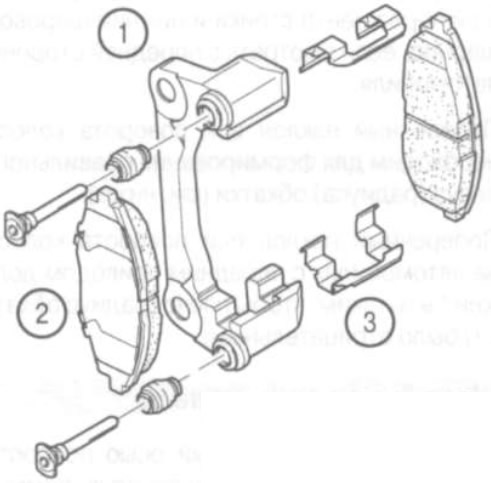

1. Fixed caliper bracket.

2. Brake pads.

3. Springs that prevent the rattling of the pads.

Replacing the rear brake pads

Replacing the rear brake pads is described in chapter «brakes».

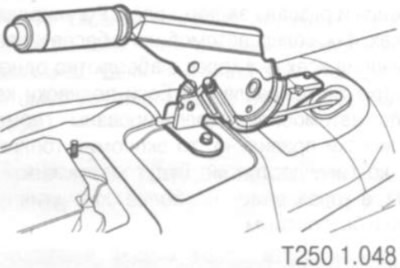

Parking brake adjustment

1. Adjust the clearance in the rear brakes by repeatedly (at least 10 times) on the brake pedal until the correct clearance is set.

2. Release the parking brake and check that the drive cables move freely.

3. Move the driver's seat back to provide enough room for work.

4. Raise and secure the vehicle so that the rear wheels can be rotated.

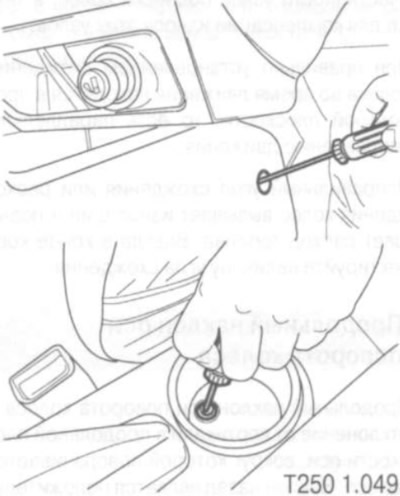

5. Remove the console trim to provide access to the lever attachment points and to the adjusting nut. To do this, remove the caps of the screws that secure the cladding to the brackets and unscrew the screws.

6. Adjust the tension of the parking brake cables by tightening the adjusting nut until the wheel has a noticeable resistance to rotation.

7. Reduce the tension of the cables by unscrewing the adjusting nut until the braked wheel is completely released. This will complete the adjustment.

Attention: this adjustment is only an adjustment for the parking brake actuator. Pay attention to how correctly adjusted the gaps between the pads and brake drums (see point 1).