Withdrawal

1. Raise and secure the vehicle.

2. Remove wheels.

3. Remove the lower engine protection trays,

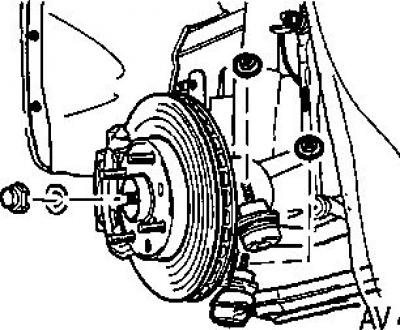

4. Turn off a nut of fastening of a power shaft in a forward nave.

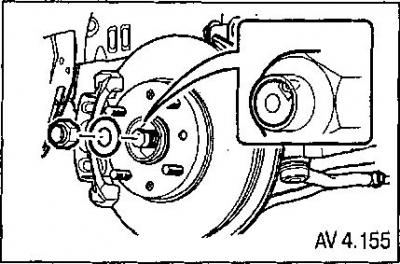

5. Turn off a nut of fastening of a steering tip to a rotary fist.

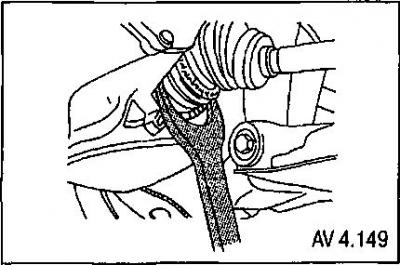

6. Disconnect the tie rod end using a ball joint puller.

7. Turn off a nut of fastening of a spherical support to a rotary fist.

8. Disconnect the steering knuckle from the ball joint using a ball joint remover.

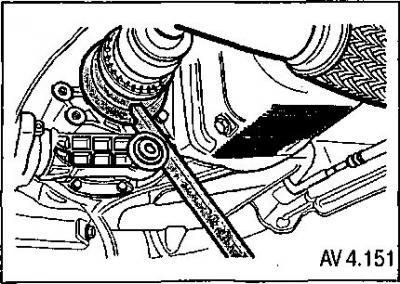

9. Push the hub axle out of the wheel hub.

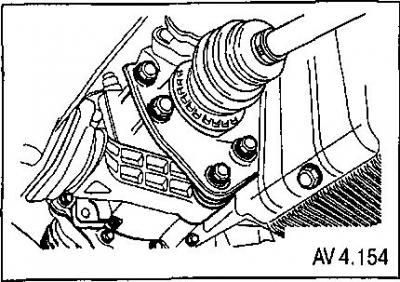

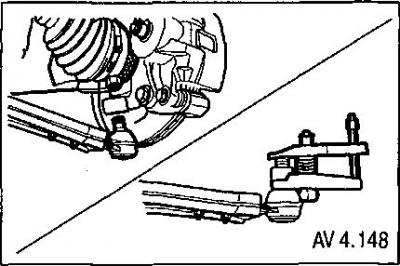

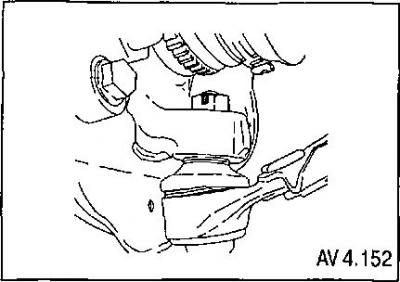

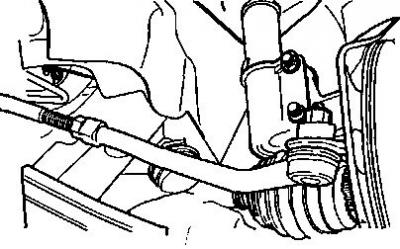

10. Remove the drive shaft from the gearbox housing using a drive shaft puller.

Paragraphs 11-16 describe the steps for removing the drive shaft on a car with automatic transmission.

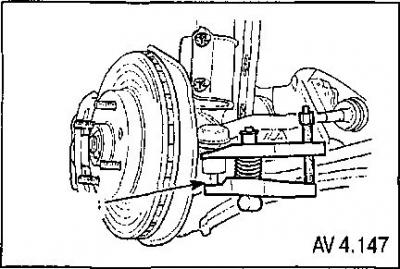

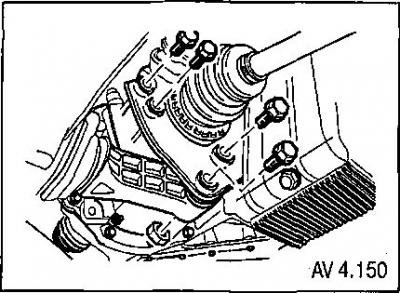

11. Remove the union nut and damping block bolt of the rear powertrain suspension bracket.

12. Remove the rear bracket bolts and powertrain suspension bracket.

13. Remove the union nut and damping block bolt of the rear powertrain suspension bracket.

14. Remove the rear bracket bolts and powertrain suspension bracket.

15. Push the main drive shaft out of the wheel hub.

16. Remove the drive shaft from the gearbox housing using a drive shaft puller.

Caution: Be sure to support the disconnected end of the drive axle. Do not allow the drive shaft to hang freely from the axle gearbox housing after it has been disengaged from the wheel hub. Place a container under the transmission case to collect any fluid that flows out of it. After removing the drive shaft, cover the opening of the gearbox housing to keep fluid in the housing and prevent dirt from entering inside.

Installation

1. Clean the hub and gearbox housing seals.

2. Install the drive shaft in the final drive.

3. Install the wheel hub onto the splined end of the drive shaft.

4. (For vehicles with automatic transmission) Install the bracket and rear bracket bolts, tightening them to 60 Nm.

5. (For vehicles with automatic transmission) Install damping block bolt and tighten to 80 Nm.

6. Connect a rotary fist with a spherical support.

7. Connect the tie rod end to the steering knuckle by tightening the nut to 45 Nm.

8. Install the ball joint nut and tighten to 50 Nm.

7. Fit a new driveshaft nut without tightening it. Always use only a new nut.

9. Install the wheels.

10. Fit the nuts without tightening them.

11. Lower the car. Tighten. Tighten the wheel nuts to 120 Nm.

12. Tighten the drive shaft nut to 300 Nm.

13. Fix the nut on the hub axle by pressing the thin edge of the nut into the longitudinal groove of the hub axle using a center punch and a hammer.

Install the engine bottom covers.

14. Fill the gearbox housing with fluid to the correct level.