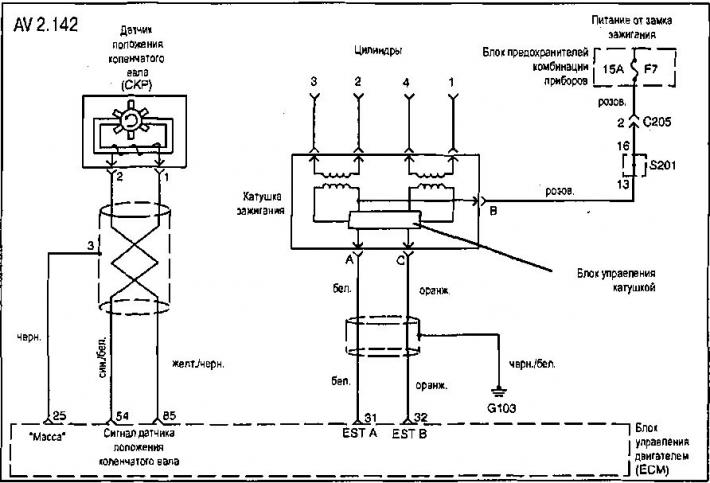

This type of ignition system without a distributor breaker works according to the method «excess spark». Cylinders are paired with opposite (1-4 or 2-3). The spark occurs simultaneously in the cylinder in which the piston is in the compression phase and in the cylinder in the exhaust phase. A cylinder in the exhaust phase requires very little energy to spark a spark plug. The rest of the energy is used by the spark plug in the cylinder during the compression phase. The ignition coil cannot be repaired, so the entire assembly must be replaced.

These systems use the EST signal from the ECM to control the electronic ignition system. The ECM uses the following data.

- Engine load (manifold or vacuum pressure).

- atmospheric (barometric) pressure.

- Engine temperature.

- Supply air temperature.

- crankshaft position.

- Engine speed (rpm).

Checking the ignition system

Check all spark plugs. Are there any damp, cracked, burnt, or heavily soiled or incorrectly gapped spark plugs. Replace spark plugs if necessary. Check for spark from all high voltage ignition wires when the starter is turned on. It is important to check for spark in all cylinders in order to detect problems with the input and output signals of the ignition coil.

Check for spark from all high voltage ignition wires when the starter is turned on.

Measure the resistance of the high voltage ignition wires (30 kOhm). Replace any high voltage ignition wires with a resistance greater than the specified value.

Check the signals from the ECM to the ignition coil. An oscilloscope is recommended when checking ECM sparking signals, as many intermittent faults can go unnoticed when using a voltmeter. If the ECM's spark signals are OK, the fault may be in the ignition coil.

Check the operation of the crankshaft position sensor, for which:

- measure the resistance between terminals 1 and 2 of the crankshaft position sensor connector (400-600 ohm) with the connector disconnected;

- measure voltage between terminals 1-3, 2 - crankshaft position sensor connector and 1 (crankshaft position sensor connector)

- G103 («weight»). In all cases, the voltage should be in the range of 1.3-1.5 V.

Disconnect the ignition coil connector. When turning on the starter, measure the voltage at terminals A and C of the ignition coil connector (0.2-2.0V). Check continuity of wires between terminals C (ignition coil connector) and A19 (ECM connector), as well as between terminals A (ignition coil connector) and A1B (ECM connector).

Check the power supply to terminal B of the ignition coil (pink wire) through connectors S201 С205 from fuse F7 (15 A) (fuse box) with a control light (probe).