Circuit Description

The ECM controls engine idle through the idle airflow valve (IAC). To increase the idle speed of the ECM, the IAC rod comes out of its socket, allowing more air to pass through the throttle body. The scanner will read the ECM commands to the IAC valve by the number of pulses.

More pulses means more bandwidth (speed increase).

The IAC valve is mounted on the throttle body to control engine idle when commanded by the engine control unit (ECM). The ECM sends voltage pulses to the IAC valve stepper motor windings to move the valve needle in or out a predetermined distance (step) with every impulse. The movement of the needle controls the valve's air flow, which in turn controls the engine's idle speed. The required idle speed for all operating conditions is set in the ECM calibrations.

Parameters affecting the idle speed control:

- coolant temperature,

- switch position Park/Neutral,

- car speed,

- battery voltage,

- pressure in the air conditioning system (if such is installed on the car).

ECM «remembers» appropriate IAC valve positions to ensure a stable warm idle speed with various combinations of the above parameters. This data is stored in the ECM ROM. The data is retained even after the ignition is switched off. The rest of the IAC valve positions are calculated from this stored data.

As a result of deviation due to wear and deviation in the minimum position of the throttle valve (within acceptable limits) have no effect on idle speed. This also means that if the power to the ECM is turned off while in parking mode, (battery removal) Possible idle control failure. This will require further depressing the accelerator pedal during engine start until the ECM locks the idle speed.

The minimum throttle position is set at the factory with the top screw. This setting allows enough air to pass through the throttle valve, which causes the throttle valve needle to move the required number of steps from its seat, to «given» Idling. The minimum throttle valve position on the engine should not be considered as setting the minimum idle speed as on other types of fuel injected engines. The top throttle screw is capped at the factory after adjustment.

Checking the idle control system (1,5L SOHC)

If the idle speed is too high, stop the engine.

Pull out the IAC idle control knob fully using the IAC actuator.

Start the engine. If the idle speed is above 800 rpm:

- find and repair a vacuum leak,

- check for throttle sticking or insufficiently tight closing,

- check that the basic idle speed settings are correct.

Inspect the IAC piping for blockages.

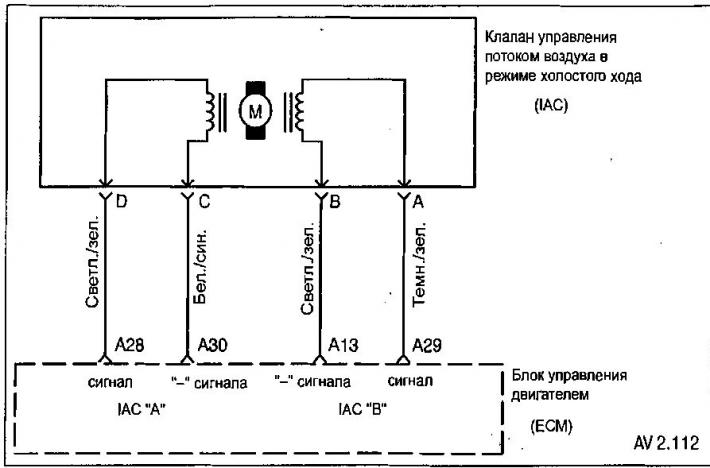

Measure the resistance between these IAC valve terminals. The resistance between terminals C and D, A and B must be (40 to 80 ohm).

Check for an open or short in the wiring between the following terminals:

- IAC valve connector D terminal and ECM connector terminal A28;

- terminal C of the IAC valve and terminal AZO of the ECM connector;

- terminal B of the IAC valve connector and terminal A13 of the ECM connector;

- terminal A of the IAC valve connector and terminal A29 of the ECM connector.

Initial setting of idle system parameters

Each time the battery cable or connector is disconnected or replaced, the following information collection procedure must be carried out.

Switch on the ignition for 5 s.

Switch off the ignition for 10 s.

Switch on the ignition for 5 s.

Start the engine in Park/Neutral.

Let the engine run until the coolant reaches 85°C.

Turn on the air conditioner for 10 seconds, if installed.

Turn off the air conditioner for 10 seconds, if installed.

If your vehicle is equipped with an automatic transmission, apply the parking brake. While depressing the brake pedal, place the shift lever in position D.

Turn on the air conditioner for 10 seconds, if installed.

Turn off the air conditioner for 10 seconds, if installed.

Switch off the ignition. The idle speed setting procedure is now complete.