Withdrawal

1. Disable «-» battery wires.

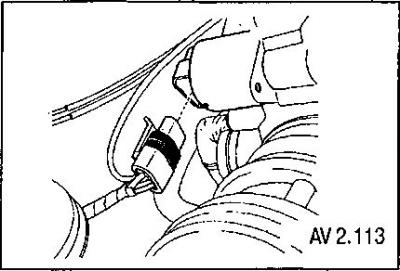

2. Remove the idle air flow control valve connector.

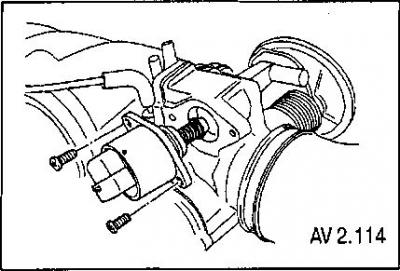

3. Remove the IAC valve mounting bolts.

Note: On IAC valves after repair, forced pushing of the valve stem is not allowed. The force required to move the stem can damage the threads on a worn actuator.

4. Remove the IAC valve.

5. Clean the IAC valve o-ring seat, stem seat, and air ducts with a suitable fuel system cleaner. Do not use methyl ethyl ketone.

Installation Caution: When installing a new IAC valve, make sure it is replaced with an identical part. The IAC valve stem geometry and diameter are designed for the specific application.

Measure the distance between the head of the IAC valve stem and the mounting flange. If the distance is more than 28mm, press the stem with your finger to push the stem back.

The force required to return the stem will not damage the IAC valve. A distance of 28 mm was set to prevent the IAC valve stem from moving out of its seat. The 28mm landing corresponds to the idle control position at start up.

1. Install a new ring on the valve, having previously lubricated it with oil.

2. Install the IAC valve on the throttle body and tighten the mounting screws to 3 Nm.

4. Plug in the IAC valve connector.

5. Connect «-» battery wire

6. Start the engine and check the idle speed.